Unit Load Devices (ULD)

Unit Load Devices (ULDs) are the standardized containers and pallets used to load cargo into aircraft. They are the fundamental building blocks of air cargo operations — allowing freight, baggage, and mail to be pre-assembled into single units that fit the precise contours of an aircraft's cargo hold. Without ULDs, loading a wide-body freighter would require handling thousands of individual packages one by one, a process that would be prohibitively slow and damage-prone.

ULDs enable faster turnaround times at airports, better space utilization inside aircraft, and reduced cargo damage through consolidated handling. Understanding ULD types and their specifications is essential for freight forwarders, ground handlers, and shippers who need to plan cargo loads efficiently.

What is a ULD

A Unit Load Device is any container or pallet that meets the certification standards set by aviation authorities and IATA for use aboard aircraft. ULDs must satisfy strict requirements:

- Structural integrity — They must withstand the forces experienced during flight, including turbulence, pressurization changes, and emergency maneuvers

- Contour compatibility — They must fit precisely into the aircraft's cargo hold, matching the curved fuselage shape of specific aircraft types

- Restraint compatibility — They must lock into the aircraft's cargo handling system (floor locks, side guides, and end stops) to prevent shifting during flight

- Weight certification — Each ULD has a certified maximum gross weight that accounts for both the device's tare weight and its contents

Every ULD must carry an IATA/airline certification tag showing its type, maximum gross weight, tare weight, and the airline that owns or manages it. ULDs that fail inspection or are damaged beyond repair limits are removed from service.

Types of ULDs

ULDs fall into two broad categories: containers (enclosed or semi-enclosed rigid shells) and pallets (flat bases used with nets and/or igloos). The choice depends on the aircraft type, cargo hold position, and the nature of the cargo being shipped.

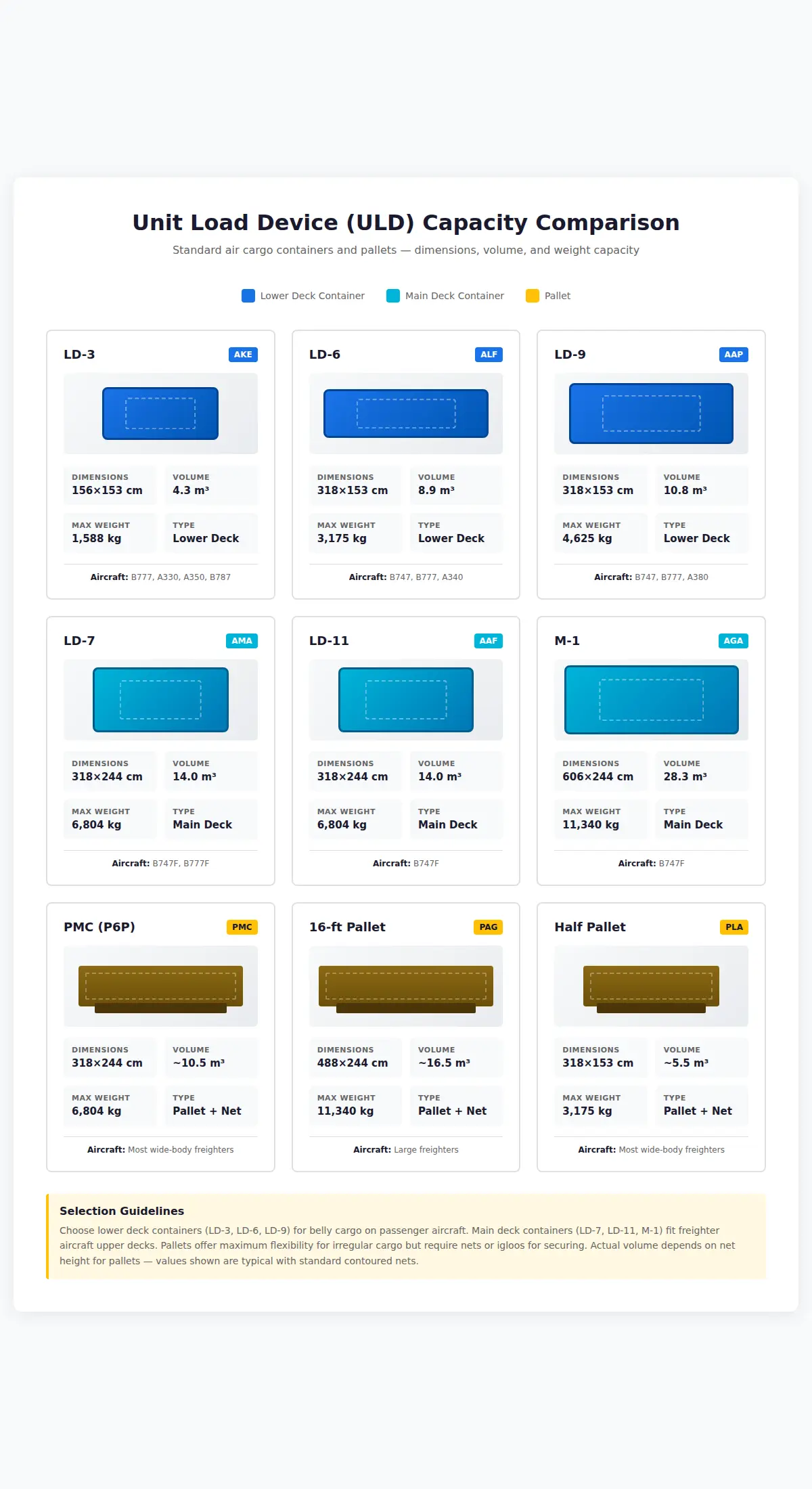

Lower Deck Containers

Lower deck containers are designed to fit into the belly holds of wide-body passenger aircraft (such as the Boeing 777, Airbus A330, or A350). Their shapes are contoured to match the curved lower fuselage.

| IATA Code | Common Name | Base Dimensions | Internal Volume | Max Gross Weight | Typical Aircraft |

|---|---|---|---|---|---|

| AKE | LD-3 | 156 × 153 cm (61.5 × 60.4 in) | 4.3 m³ (153 ft³) | 1,588 kg (3,501 lb) | B777, A330, A350, B787 |

| AKH | LD-3 (half height) | 156 × 153 cm | 2.1 m³ | 1,134 kg | Various wide-body |

| DPE | LD-2 | 120 × 153 cm (47 × 60.4 in) | 3.4 m³ (120 ft³) | 1,225 kg (2,700 lb) | A300, A310 |

| ALF | LD-6 | 318 × 153 cm (125 × 60.4 in) | 8.9 m³ (315 ft³) | 3,175 kg (7,000 lb) | B747, B777, A340 |

| AAP | LD-9 | 318 × 153 cm (125 × 60.4 in) | 10.8 m³ (381 ft³) | 4,625 kg (10,195 lb) | B747, B777, A380 |

Main Deck Containers

Main deck containers are used on freighter aircraft where the entire upper deck is configured for cargo. These are substantially larger than lower deck units.

| IATA Code | Common Name | Base Dimensions | Internal Volume | Max Gross Weight | Typical Aircraft |

|---|---|---|---|---|---|

| AMA | LD-7 | 318 × 244 cm (125 × 96 in) | 14.0 m³ (494 ft³) | 6,804 kg (15,000 lb) | B747F, B777F |

| AAF | LD-11 | 318 × 244 cm (125 × 96 in) | 14.0 m³ (494 ft³) | 6,804 kg (15,000 lb) | B747F |

| AGA | M-1 | 606 × 244 cm (238 × 96 in) | 28.3 m³ (1,000 ft³) | 11,340 kg (25,000 lb) | B747F |

Pallets

Pallets are flat aluminum bases onto which cargo is stacked and then secured with contoured nets or covered with an igloo (a rigid shell placed over the pallet). Pallets offer the most flexibility — they can carry irregularly shaped cargo, heavy machinery, or oversized items that would not fit inside a container.

| IATA Code | Common Name | Base Dimensions | Usable Volume (with net) | Max Gross Weight |

|---|---|---|---|---|

| PMC | P6P Pallet | 318 × 244 cm (125 × 96 in) | 10.5 m³ (depending on net height) | 6,804 kg (15,000 lb) |

| PAG | 16-ft Pallet | 488 × 244 cm (192 × 96 in) | 16.5 m³ | 11,340 kg (25,000 lb) |

| PLA | Half Pallet | 318 × 153 cm (125 × 60.4 in) | 5.5 m³ | 3,175 kg (7,000 lb) |

| PNA | Half Pallet (narrow) | 318 × 122 cm (125 × 48 in) | 4.2 m³ | 2,449 kg (5,400 lb) |

Specialty ULDs

Beyond standard containers and pallets, several specialty ULDs serve specific cargo types:

- Reefer containers — Temperature-controlled ULDs (e.g., LD-3 Reefer / RKN) with built-in cooling or heating systems for pharmaceuticals, perishable foods, and biological materials

- Horse stalls — Purpose-built ULDs (HMA type) for transporting live horses, featuring padded walls and ventilation

- Car racks — Twin or single car rack ULDs for automobile transport on freighter aircraft

- Hazmat igloos — Containers with fire-resistant liners for dangerous goods shipments

ULD Identification Codes

Every individual ULD is marked with a unique identifier that allows it to be tracked across the global air cargo network. The IATA ULD identification system follows a standardized format:

┌─────────────┬──────────────┬──────────┐

│ Type Code │ Serial Number│ Owner │

│ (3 letters) │ (4-5 digits) │ (2-letter│

│ │ │ airline) │

├─────────────┼──────────────┼──────────┤

│ AKE │ 12345 │ LH │

│ (LD-3 │ (Unique unit │(Lufthansa│

│ container) │ identifier) │ owned) │

└─────────────┴──────────────┴──────────┘

Full ID: AKE 12345 LH

- Type code (3 letters): The first letter indicates the ULD category (A = certified aircraft container, P = aircraft pallet, R = thermal/reefer). The second and third letters identify the specific design variant.

- Serial number (4–5 digits): A unique number assigned to that individual unit by the owning airline.

- Owner code (2 letters): The IATA two-letter airline designator of the airline that owns the ULD.

This system enables ULD tracking across airlines, ground handlers, and airports worldwide — critical for managing a fleet where ULDs constantly move between carriers and locations.

Weight and Volume Limitations

Every ULD has two critical limits that must not be exceeded:

Maximum Gross Weight

The maximum gross weight includes the tare weight of the ULD itself plus the weight of its contents. Exceeding this limit compromises the structural integrity of the ULD and may violate aircraft load limitations.

Structural and Aircraft Limits

Even when a ULD is within its own weight limit, the aircraft floor loading limit (expressed in kilograms per running meter or per pallet position) may impose a lower effective maximum. The aircraft's center of gravity (CG) envelope also dictates how weight can be distributed across cargo positions.

Volume vs Weight Trade-off

For lightweight but bulky cargo, the ULD may "cube out" (reach volume capacity) before it "weighs out" (reaches weight limits). Conversely, dense cargo like machinery or metal parts will reach weight limits while leaving significant volume unused. This trade-off directly affects chargeable weight calculations and shipment economics.

Freight forwarders maximize profitability by combining dense and voluminous cargo in the same ULD — the dense cargo uses weight capacity while the voluminous cargo fills remaining space. This practice, called co-loading, improves both weight and volume utilization.

ULD Management and Tracking

Airlines collectively own and manage millions of ULDs worldwide. Managing this fleet is a complex logistics challenge in its own right.

Interline Transfer Agreements

When an airline's ULD is transferred to another carrier (e.g., during an interline shipment), IATA Transfer Conditions govern the arrangement. The receiving airline assumes responsibility for the ULD and must return it within agreed timeframes or face demurrage-like charges. The IATA ULD Transfer Message (UCM) tracks these transfers electronically.

ULD Control and Positioning

Airlines employ dedicated ULD control departments that track:

- Current location of every ULD in the fleet (airport, aircraft, warehouse)

- Condition status — serviceable, damaged, or awaiting repair

- Stock levels at each station — ensuring enough empty ULDs are positioned where demand exists

- Utilization rates — identifying underperforming stations or routes where ULDs accumulate

Digital Tracking

Modern ULD management increasingly uses digital tracking technologies:

- Bluetooth Low Energy (BLE) tags attached to ULDs that report location when within range of airport readers

- RFID tags for automated scanning during handling

- IoT sensors that monitor not only location but also temperature, shock events, and light exposure (door opening) — particularly valuable for temperature-sensitive cargo

- Cloud-based ULD management platforms that aggregate tracking data across the fleet

Repair and Maintenance

ULDs undergo regular inspection and maintenance:

- Pre-load inspection — Ground handlers check for visible damage before loading

- Periodic inspection — Detailed structural checks per IATA standards (typically every 12–18 months)

- Damage repair — Minor repairs (dent removal, net replacement) at local stations; major repairs at certified ULD repair shops

- Retirement — ULDs exceeding damage thresholds or age limits are retired and scrapped

Resources

| Resource | Description | Link |

|---|---|---|

| IATA ULD Regulations (ULDR) | Official IATA standards for ULD design, testing, repair, and operational use | iata.org/uld |

| AirBridgeCargo ULD Specifications | Detailed specification sheets for common container and pallet types | airbridgecargo.com/uld |

| ANA Cargo ULD & Aircraft Specs | Visual reference for pallet and container dimensions by aircraft type | anacargo.jp/specification |

| SeaRates ULD Reference | Quick-reference specifications for all common ULD types with rate classes | searates.com/uld |

| IATA ULD CARE Program | Industry best practices for ULD handling, reducing damage and loss | iata.org/uld-care |

Related Topics

- Air Waybill — The transport document that references ULD types and piece counts

- Dimensional Weight — How cargo dimensions and ULD utilization affect chargeable weight

- Airport Operations — How ULDs are built up, broken down, and moved through cargo terminals

- Container Types — The ocean freight equivalent of ULDs for comparison

- Dangerous Goods — Special ULD requirements for hazardous materials