Airport Cargo Operations

Air cargo passes through a structured chain of processes at airport freight terminals — from the moment goods arrive at the origin warehouse until they are released to the consignee at destination. These operations involve multiple parties working under tight schedules, strict security mandates, and complex documentation requirements.

Understanding airport cargo operations helps freight forwarders manage transit times, avoid delays, anticipate costs (storage, handling), and ensure shipments comply with security and regulatory requirements at every handoff point.

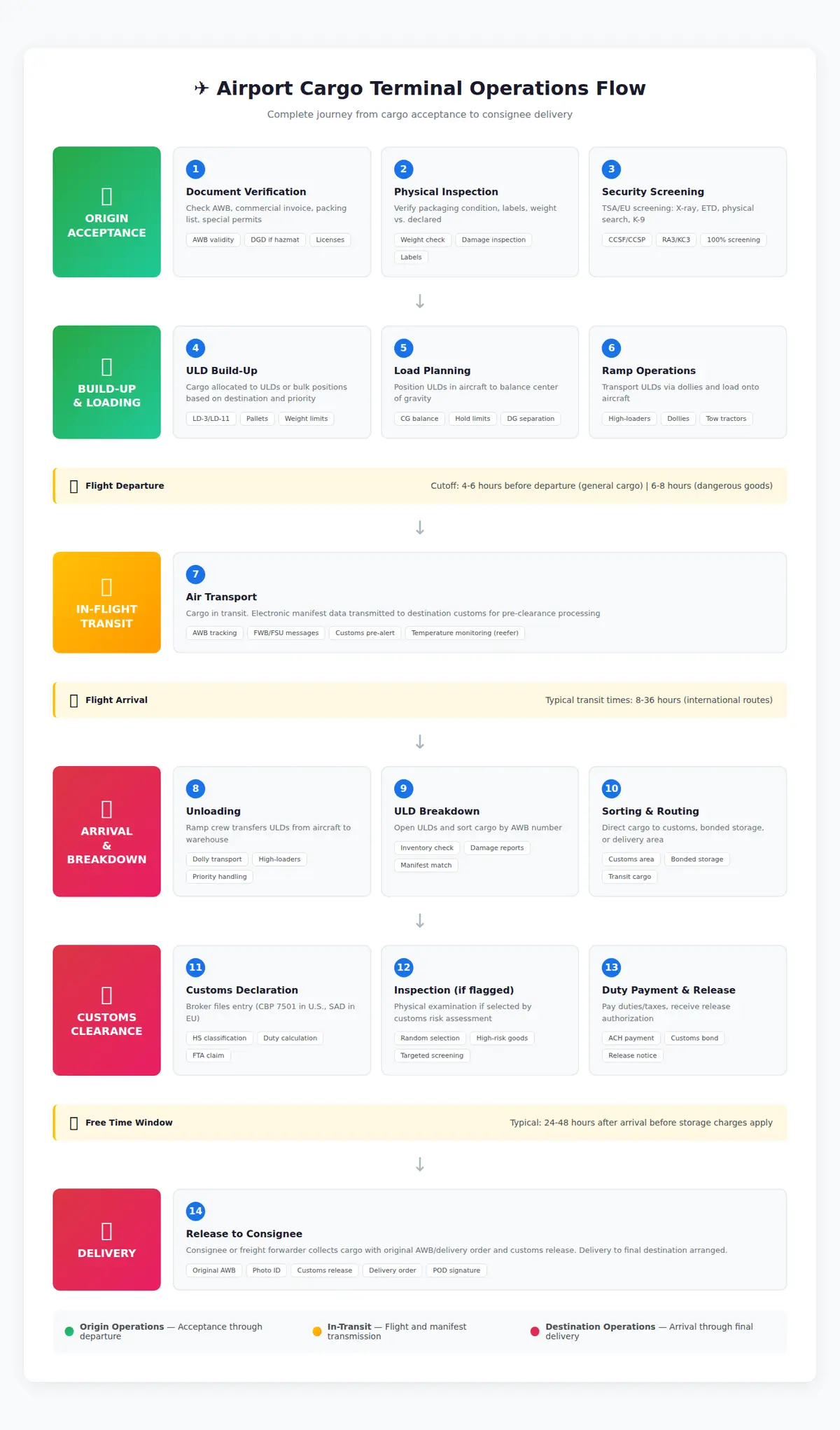

Complete Terminal Operations Flow

The following visual details every step from cargo acceptance at origin through final delivery at destination, including security screening, ULD build-up, flight operations, customs clearance, and release procedures:

Flow highlights:

- Origin (Steps 1-6): Acceptance cut-off is typically 4-6 hours before departure for general cargo, 6-8 hours for dangerous goods

- Transit (Step 7): Electronic manifest data transmitted during flight for customs pre-clearance at destination

- Destination (Steps 8-14): Free time window is usually 24-48 hours after arrival before storage charges apply

- Color coding: Green = Origin operations | Yellow = In-transit | Red = Destination operations

Cargo Acceptance and Screening

Acceptance is the first critical checkpoint in airport cargo operations. When freight arrives at the airline's warehouse (or ground handler's facility), it undergoes a series of verification steps before it is admitted into the secure cargo system.

The Acceptance Process

| Step | Activity | What's Checked |

|---|---|---|

| 1 | Document verification | AWB, commercial invoice, packing list, special documents (DGD, CITES permits, phytosanitary certificates) |

| 2 | Physical inspection | Package condition, markings, labels — damaged or improperly labeled cargo is rejected |

| 3 | Weight and dimensions | Actual weight vs. declared weight; dimensions for ULD planning and chargeable weight verification |

| 4 | Special cargo check | Dangerous goods acceptance check (for DG shipments), temperature validation (for perishables), live animal compliance |

| 5 | Ready-for-carriage check | Final confirmation that documentation matches physical shipment, all embargoes and restrictions applied |

The most frequent causes of cargo rejection at acceptance are:

- Weight discrepancy — actual weight exceeds declared weight beyond tolerance (usually ±0.5%)

- Missing or incorrect documentation — especially for dangerous goods, perishables, and valuable cargo

- Packaging damage — torn outer cartons, crushed corners, moisture damage

- Incorrect labeling — missing hazard labels, orientation arrows, or handling instructions

Security Screening

All air cargo must be screened before loading onto aircraft. The approach varies by jurisdiction but follows the principle of 100% screening for all cargo on passenger flights.

United States (TSA)

The Certified Cargo Screening Program (CCSP) allows screening to happen at multiple points in the supply chain:

- CCSF (Certified Cargo Screening Facility) — TSA-certified warehouses, 3PLs, and shippers that screen cargo before it enters the air transport chain

- Known Shipper Program — registered shippers with TSA-vetted security history may tender cargo with reduced screening requirements

- Screening methods — X-ray, explosive trace detection (ETD), physical search, canine teams (3PK9-C certified), and explosive detection systems (EDS)

European Union (RA3/KC3)

The EU operates a Regulated Agent (RA3) and Known Consignor (KC3) system:

- RA3 — entities approved by an EU aviation security authority to screen and secure cargo

- KC3 — shippers whose security procedures are validated, allowing cargo to be accepted without additional screening at the airline

- Screening must comply with EU Regulation 2015/1998 and the ACC3 (Air Cargo or Mail Carrier operating into the EU from a Third Country) framework

Acceptance Cut-Off Times

Airlines publish cargo acceptance cut-off times that define the latest point at which freight can be tendered:

| Cargo Type | Typical Cut-Off (Before Departure) |

|---|---|

| General cargo | 4–6 hours |

| Dangerous goods | 6–8 hours |

| Live animals | 4–6 hours |

| Perishables | 3–5 hours |

| Known shipper / pre-screened | 3–4 hours |

Missing the cut-off means the shipment rolls to the next available flight, potentially adding 24+ hours to transit time.

Build-Up and Loading

Once cargo is accepted and screened, it moves to the build-up area where it is assembled into Unit Load Devices (ULDs) or prepared for bulk loading.

Build-Up Process

- Cargo allocation — the warehouse management system (WMS) assigns shipments to specific ULDs based on destination, flight, priority, and compatibility

- ULD serviceability check — each ULD is inspected for structural integrity, correct door operation, and airworthiness markings before use

- Loading the ULD — cargo is arranged inside the ULD to maximize space utilization while respecting weight limits and segregation rules (e.g., dangerous goods classes that cannot be loaded together)

- Weighing and dimensioning — the built-up ULD is weighed; the load manifest is updated with actual weights

- Net or door securing — containers are closed and locked; pallets are netted and strapped to prevent shifting during flight

Airlines use load planning systems (sometimes called weight and balance systems) to determine where each ULD is positioned in the aircraft. The goal is to keep the aircraft's center of gravity (CG) within safe limits while maximizing payload. Load planners must account for:

- Forward and aft cargo hold capacities and weight limits

- Structural floor loading limits per ULD position

- Hazardous goods loading positions (DG must be accessible and separated)

- Priority of offloading at intermediate stops

Ramp Operations

The physical transfer between warehouse and aircraft is handled by the ramp crew:

| Equipment | Purpose |

|---|---|

| Dollies | Low-profile trailers that carry ULDs between warehouse and aircraft |

| Tow tractors | Pull dolly trains across the tarmac |

| High-loaders | Elevating platforms that lift ULDs to main-deck cargo door height |

| Belt loaders | Conveyors for loading loose (bulk) cargo into lower holds |

| ULD transporters | Self-propelled vehicles for heavy ULDs at large hub airports |

The turnaround window — the time between an aircraft's arrival and departure — is typically 1–3 hours for freighters and 45–90 minutes for passenger aircraft belly cargo. Every minute counts.

Arrival and Breakdown

At the destination airport, the process reverses:

Breakdown Process

- Unloading — ramp crew transfers ULDs from aircraft to warehouse using the same equipment as departure

- ULD breakdown — containers and pallets are opened, cargo is sorted by Air Waybill number

- Inventory check — each piece is verified against the flight manifest; discrepancies (shortages, damages, overages) are recorded as irregularity reports

- Customs pre-clearance — in many countries, electronic manifest data is transmitted before aircraft arrival, enabling advance clearance for low-risk shipments

- Sorting — cargo is directed to: customs examination area, bonded storage, transit area (for connecting flights), or the delivery bay

Transit and Transfer Cargo

Cargo connecting through a hub airport may be transited (remaining in the secure area) or transferred (broken down and rebuilt into a different ULD for the onward flight). Transfer cargo adds complexity:

- New ULD build-up for the next flight

- Possible re-screening if the transfer breaks the secure chain

- Additional handling increases the risk of damage or delay

- Minimum Connection Time (MCT) for cargo is typically longer than for passengers — 4–8 hours at major hubs

Cargo Delivery and Release

The final stage of airport cargo operations is the release of freight to the consignee or their authorized agent.

Release Requirements

To collect cargo, the consignee must present:

| Document | Purpose |

|---|---|

| Original AWB or delivery order | Proves right to receive the cargo |

| Customs clearance | Confirms duties paid or exemption granted |

| Government permits | If applicable (e.g., FDA release for food, USDA for agricultural products) |

| Photo identification | Verifies the collecting party's identity |

Storage and Demurrage

Cargo not collected promptly incurs storage charges:

| Period | Typical Charge |

|---|---|

| Free time | 24–48 hours after flight arrival (varies by airline/station) |

| Days 3–5 | $0.05–0.15 per kg per day |

| Days 6+ | $0.10–0.30 per kg per day (escalating) |

| After 30+ days | Cargo may be declared abandoned and auctioned or destroyed |

Freight forwarders monitor flight arrivals and pre-arrange customs clearance so that cargo can be collected within the free time window. Many use cargo tracking systems that provide automated alerts when a shipment's flight lands, triggering the delivery process immediately.

Delivery Methods

- Consignee pickup — the consignee or their agent collects cargo directly from the airline warehouse

- Forwarder delivery — a freight forwarder collects and delivers to the consignee's premises (the most common model)

- Airline delivery — some airlines offer door-to-door service, arranging trucking from the airport

- Cross-dock — at major cargo hubs, shipments may be transferred directly to a trucking carrier without entering warehouse storage

Ground Handling Agents (GHAs)

Most airlines do not operate their own cargo warehouses. Instead, they contract Ground Handling Agents (GHAs) to provide cargo services at each airport.

Services Provided by GHAs

| Service Category | Activities |

|---|---|

| Warehouse operations | Cargo acceptance, storage, build-up, breakdown, delivery |

| Ramp handling | ULD transport, aircraft loading/unloading |

| Documentation | Manifest preparation, customs coordination, AWB data capture |

| ULD management | ULD storage, serviceability checks, repair coordination |

| Special cargo | Temperature-controlled storage, DG handling, live animal care, valuable cargo security |

The IATA Standard Ground Handling Agreement (SGHA)

The SGHA (published in the IATA Airport Handling Manual, AHM 810) is the industry-standard contract between airlines and GHAs. It provides:

- A Main Agreement with standard legal terms (liability, insurance, indemnification)

- Annex A listing all possible services a GHA can provide

- Annex B specifying which services are selected for the particular station, along with any special requirements

- A complementary Service Level Agreement (SLA) that defines performance metrics (e.g., cargo build-up completion 3 hours before departure, breakdown within 2 hours of arrival)

Major GHA Companies

The ground handling industry is concentrated among several global providers:

- Swissport — world's largest aviation services provider, operating at 300+ airports

- dnata — Dubai-based handler present across six continents

- Menzies Aviation — major handler recently acquired by Agility

- WFS (Worldwide Flight Services) — significant cargo handler, now part of SATS

- Çelebi Aviation — major handler in Europe and Asia

Airlines evaluate GHAs on operational reliability (on-time performance, cargo damage rates), compliance (security screening accuracy, DG acceptance quality), and technology (electronic messaging, real-time tracking, digital acceptance).

Technology in Airport Cargo Operations

Modern cargo terminals increasingly rely on technology to improve efficiency and visibility:

| Technology | Application |

|---|---|

| Cargo Community Systems (CCS) | Shared platforms connecting airlines, GHAs, forwarders, and customs (e.g., CHAMP Traxon, NALLIAN) |

| IATA Cargo-XML / ONE Record | Standardized electronic messaging replacing paper documents |

| Automated Storage and Retrieval | Robotic systems for storing and retrieving cargo in high-density warehouses |

| RFID/IoT tracking | Real-time location and condition monitoring of ULDs and individual shipments |

| AI-powered load planning | Optimization algorithms for ULD build-up and aircraft loading |

| e-Freight | IATA initiative to eliminate paper from air cargo — digitizing AWBs, customs declarations, and DG documents |

ONE Record is IATA's initiative to create a single, standardized digital record for every shipment. Instead of passing documents between parties, all stakeholders access and update a shared data record via APIs. This reduces data entry errors, speeds up processing, and provides end-to-end visibility across the air cargo chain.

Resources

| Resource | Description | Link |

|---|---|---|

| IATA Cargo Handling | Overview of air cargo handling standards and best practices | iata.org/cargo-handling |

| IATA SGHA Overview | Explanation of the Standard Ground Handling Agreement framework | iata.org/sgha |

| TSA Cargo Screening Program | U.S. TSA requirements for air cargo screening (CCSP, CCSF, 3PK9) | tsa.gov/cargo-screening |

| FAA Cargo Safety | U.S. FAA regulations and advisories for air cargo operations | faa.gov/hazmat |

| IATA ONE Record | Information on IATA's digital cargo data-sharing initiative | iata.org/one-record |

Related Topics

- Air Waybill — the primary document governing cargo through every stage of airport operations

- ULD Types — the containers and pallets used in build-up and loading

- Dangerous Goods — special acceptance and handling procedures for hazardous cargo

- Dimensional Weight — how weight and dimensions verified at acceptance determine charges

- Port Operations — comparable terminal operations in ocean freight