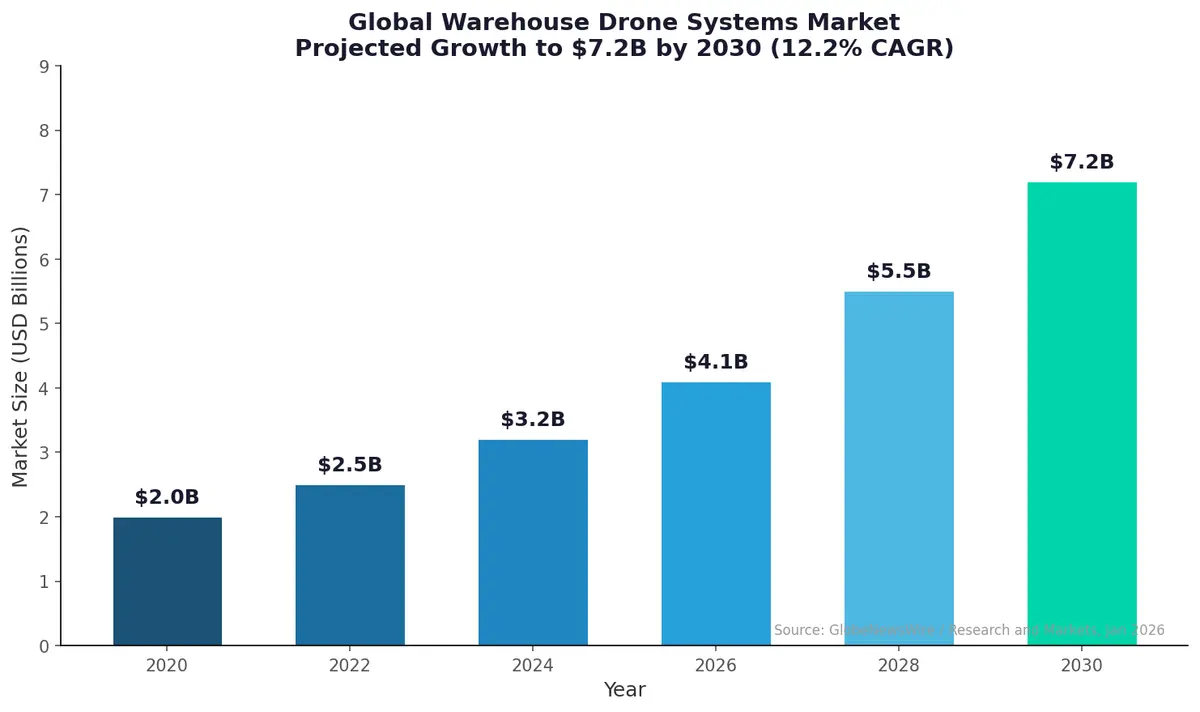

Warehouse Drones Hit $7.2 Billion: How Autonomous Inventory Scanning Is Replacing Manual Cycle Counts

The warehouse drone market is on track to hit $7.2 billion by 2030, growing at a 12.2% CAGR according to a January 2026 market research report.

But this isn't about drones delivering packages to your doorstep. It's about what's happening inside the warehouse — where autonomous drones are quietly making one of logistics' most tedious tasks obsolete.

The Problem Manual Cycle Counts Can't Solve

Inventory inaccuracy is a trillion-dollar problem. Industry estimates peg the global cost of inventory distortion — shrinkage, stockouts, and overstocking combined — at $1.1 trillion annually. At the warehouse level, even well-run operations typically achieve only 63-80% inventory accuracy with manual cycle counting processes.

The traditional cycle count is a painful ritual. Workers armed with scanners and clipboards walk aisles, climb ladders, and squint at barcodes on pallets stacked 30-40 feet high. It's slow, dangerous, and inherently error-prone. A single large distribution center might need weeks to complete a full physical inventory, during which normal operations grind to a halt.

The math doesn't work anymore. With SKU proliferation accelerating and same-day fulfillment expectations becoming standard, warehouses need real-time inventory visibility — not quarterly snapshots.

How Warehouse Drones Actually Work

Modern warehouse drones are nothing like the consumer quadcopters you see at the park. Systems like the Corvus One from Corvus Robotics are purpose-built for indoor environments, equipped with AI-powered computer vision, barcode and RFID scanning capabilities, and autonomous navigation systems that let them fly through narrow aisles without human guidance.

Here's the typical workflow:

- Autonomous flight planning — The drone maps the warehouse and creates optimized flight paths to scan every pallet location

- Multi-sensor scanning — Cameras, barcode readers, and RFID antennas capture inventory data from floor to ceiling

- AI-powered analysis — Computer vision algorithms read labels, detect misplaced items, and identify empty slots

- WMS integration — Scan results feed directly into the warehouse management system, flagging discrepancies in real time

The result: a full warehouse scan that once took a team of workers several days can now be completed by a single drone in hours — and it can run nightly without interrupting operations.

The Cold Chain Breakthrough

One of the most compelling recent developments is Corvus Robotics' launch of Corvus One for Cold Chain in February 2026. This system is designed to operate autonomously in freezer warehouses at temperatures as low as minus 20°F.

Cold chain warehouses have always been the worst environment for manual cycle counts. Workers can only endure sub-zero conditions for short shifts, even with specialized gear. Turnover in cold storage positions runs significantly higher than ambient warehouse roles. Sending a drone into the freezer instead eliminates the human safety risk entirely while delivering more accurate and more frequent inventory scans.

This is the kind of application where the ROI case writes itself: fewer worker injuries, lower labor costs, and dramatically better inventory accuracy in an environment where misplaced pallets of frozen goods can mean thousands of dollars in spoilage.

ROI: The Numbers That Matter

The business case for warehouse drones centers on three pillars:

Speed. Drone-based scanning is 3-5x faster than manual cycle counting. A drone can scan an entire aisle of high-bay racking in minutes rather than hours, and it doesn't need breaks, ladders, or safety spotters.

Accuracy. Facilities using drone inventory systems report accuracy rates of 98-99%, according to industry assessments. Compare that to the 63-80% accuracy typical of manual counts, and the gap becomes a competitive advantage.

Frequency. Perhaps the biggest shift is from periodic to continuous counting. Instead of quarterly physical inventories or rotating cycle counts, drones enable daily full-facility scans. Discrepancies are caught in hours, not months. Stockouts are prevented before they happen. Phantom inventory — items the WMS thinks exist but don't — gets eliminated.

For a mid-size DC processing 50,000+ SKUs, the labor savings alone from eliminating manual cycle counts can reach $200,000-$500,000 annually, before accounting for the revenue impact of improved fill rates and reduced shrinkage.

Key Players Shaping the Market

The warehouse drone space is maturing rapidly. Beyond Corvus Robotics, several companies are driving innovation:

- Gather AI — Focuses on inventory intelligence with drone-captured visual data and AI analytics

- Verity — Swiss-based company offering autonomous indoor drones with a focus on location intelligence

- Flytrex — While known for delivery drones, their warehouse scanning capabilities are expanding

- Ware (acquired by Stow Group) — Pioneered drone-based cycle counting for pallet racking

The competitive landscape is driving prices down and capabilities up. AI and machine learning for predictive operations, swarm drone systems that can scan entire facilities simultaneously, and improved battery technology for longer flight times are all advancing rapidly.

Integration Is Everything

A warehouse drone is only as valuable as its connection to the broader logistics ecosystem. The real power emerges when drone-captured inventory data flows seamlessly into your WMS, TMS, and order management systems.

When a drone scan reveals that Bay 42, Level 5 contains Product X instead of the expected Product Y, that information needs to trigger immediate action — a WMS correction, an updated pick path, and potentially a replenishment order. Without tight integration, you're just collecting expensive aerial photographs.

This is where platforms like CXTMS add critical value. By connecting warehouse-level inventory data with transportation planning and order fulfillment workflows, discrepancies caught by drones can ripple through the entire supply chain in real time. A stockout detected at 2 AM by an autonomous drone scan can trigger a replenishment shipment before the morning shift even starts.

What's Coming Next

The trajectory is clear. By 2030, autonomous inventory drones will be standard equipment in large distribution centers, much like conveyor systems and barcode scanners are today. The convergence of better AI, longer battery life, and falling hardware costs is making the technology accessible to mid-market warehouses, not just enterprise giants.

Swarm technology — multiple drones coordinating to scan an entire facility simultaneously — is the next frontier. Combined with digital twin platforms that maintain a real-time virtual replica of the physical warehouse, we're moving toward a world where inventory data is always current, always accurate, and always actionable.

For logistics operators still relying on manual cycle counts, the window to gain competitive advantage from early adoption is closing. The question isn't whether warehouse drones will become standard — it's whether you'll be ahead of the curve or playing catch-up.

Ready to connect real-time warehouse data with your transportation and fulfillment workflows? Contact CXTMS for a demo of our integrated logistics platform.