Warehouse Zones

Warehouses are divided into distinct functional zones, each designed to support a specific stage of the material handling process. Proper zone design ensures efficient product flow from inbound receipt through storage, order fulfillment, and outbound shipping, while minimizing congestion and unnecessary movement. Understanding how zones work together is fundamental to warehouse operations and layout optimization.

Why Zoning Matters

Zoning is the practice of dividing a warehouse into designated areas based on function, product characteristics, or operational requirements. Well-designed zones deliver several critical benefits:

- Reduced travel distance — By positioning related activities close together and sequencing zones to match product flow, workers and equipment spend less time moving between tasks.

- Improved throughput — Dedicated areas for each function prevent bottlenecks and allow parallel processing (e.g., receiving and shipping can occur simultaneously without interference).

- Better space utilization — Different zones have different space requirements; proper allocation ensures high-density storage where appropriate and open space where workflows demand it.

- Enhanced safety — Separating forklift traffic from manual picking areas, isolating hazardous materials, and controlling congestion points reduce accident risk.

- Operational clarity — Clear zone boundaries make it easier to assign tasks, train new workers, and troubleshoot inefficiencies.

Most warehouses use a combination of fixed zones (permanent areas designated for specific functions like receiving or shipping) and flexible zones (areas that can be reconfigured based on seasonal demand or operational changes).

Core Warehouse Zones

While warehouse layouts vary based on industry, product mix, and operational strategy, most facilities include the following core functional zones:

Receiving Zone

The receiving zone (or inbound dock area) is where goods enter the warehouse. This zone typically includes:

- Dock doors and staging lanes for inbound trucks

- Unloading areas with forklifts, pallet jacks, and dock plates

- Inspection stations for verifying shipment accuracy and documenting receipt

- Temporary holding areas for goods awaiting putaway

Receiving zones are often located along one side of the building with direct truck access. High-volume facilities may dedicate multiple doors to receiving, with separate lanes for full truckloads (FTL), less-than-truckload (LTL), and express deliveries.

Position receiving docks close to bulk storage or staging areas to minimize the distance goods must travel after unloading. Avoid placing receiving and shipping on the same wall unless you have a through-flow or U-shaped layout designed for cross-docking.

Quality Control & Inspection

The QC/Inspection zone is where inbound goods are verified for accuracy, condition, and compliance before entering inventory. Depending on the operation, this may be a dedicated area adjacent to receiving or integrated into the receiving workflow.

Inspection activities include:

- Count verification — Confirming quantities match the purchase order and packing list

- Condition assessment — Checking for damage, expiration dates, or quality issues

- Compliance checks — Verifying lot numbers, certifications, or regulatory requirements (e.g., HACCP for food, FDA for pharmaceuticals)

Goods that fail inspection are routed to a quarantine or hold area for disposition (return, rework, or disposal).

Bulk Storage (Reserve Storage)

Bulk storage (also called reserve storage) is where full pallets of inventory are stored at high density until needed for order fulfillment. This zone prioritizes space efficiency over accessibility, often using:

- Selective pallet racking for direct pallet access

- Drive-in or push-back racking for high-density storage of homogeneous SKUs

- Block stacking (floor stacking) for stable, stackable goods

Bulk storage typically accounts for 60-80% of total warehouse space and is designed for forklift access. Slower-moving items and overflow inventory are often stored deeper in the facility, while faster-moving SKUs are kept closer to picking zones.

Forward Pick Zone (Active Picking)

The forward pick zone (or active picking zone) is where individual cases or items (eaches) are selected to fulfill customer orders. Unlike bulk storage, which handles full pallets, forward pick zones are optimized for item-level access and high activity.

Common configurations include:

- Flow racks or carton flow systems that present products at an ergonomic height

- Shelving or bin locations for small-parts picking

- Pick modules that combine multiple SKUs in a compact, accessible layout

Forward pick zones are typically replenished from bulk storage, either automatically (via conveyors or AS/RS) or manually (via forklifts or pallet jacks). Replenishment frequency depends on pick velocity—high-demand items may be replenished multiple times per shift.

Many warehouses use slotting optimization to position the fastest-moving SKUs in the most accessible forward pick locations, reducing travel time and improving order throughput.

Packing Zone

The packing zone (or pack station area) is where picked items are consolidated, verified, and packaged for shipment. Packing activities include:

- Order verification — Confirming all items for an order are present and correct

- Cartonization — Selecting appropriate box sizes and packing materials

- Labeling — Applying shipping labels, barcodes, and compliance documentation

- Weighing and dimensioning — Capturing package dimensions for carrier billing

Packing zones are typically located between the picking area and the shipping dock, with workstations equipped with scales, label printers, tape dispensers, and dunnage (packing materials). High-volume operations may use automated packing systems or pack-and-ship conveyors to streamline this process.

Shipping Zone (Outbound Dock)

The shipping zone is where packed orders are staged, sorted by carrier or route, and loaded onto outbound trucks. This zone mirrors the receiving area in layout but focuses on outbound flow.

Key features include:

- Staging lanes organized by carrier, route, or delivery date

- Dock doors for truck loading

- Manifesting stations for generating bills of lading and shipment documentation

- Last-mile sorting for parcel carriers (UPS, FedEx, USPS)

In high-throughput facilities, shipping zones may use automated sortation systems to route packages to the correct door based on carrier or destination.

Avoid dock congestion by scheduling outbound truck appointments and maintaining clear staging lanes. Mixed-use docks (receiving and shipping) require strict traffic control to prevent gridlock during peak periods.

Returns & Reverse Logistics

The returns zone handles goods coming back from customers or field locations. This area requires special workflows for:

- Inspection and disposition — Determining whether returned items can be restocked, need repair, or must be scrapped

- Repackaging — Preparing resalable returns for inventory

- Customer credits — Processing refunds or exchanges

- Vendor returns — Routing defective goods back to suppliers

Returns zones are often located near receiving (since both involve inbound goods) but kept separate to avoid contamination of new inventory with returned or damaged products.

Value-Added Services (VAS)

Some warehouses include a value-added services zone for activities beyond basic storage and fulfillment, such as:

- Kitting and assembly — Combining multiple SKUs into bundled products

- Labeling and repackaging — Applying custom branding or compliance labels

- Light manufacturing — Final product assembly or customization

- Quality testing — Pre-shipment inspections or product testing

VAS zones are typically separate from high-velocity picking areas to avoid workflow interference.

Warehouse Zone Characteristics

The following table compares key characteristics of common warehouse zones:

| Zone | % of Space | Labor Intensity | Equipment | Primary Flow |

|---|---|---|---|---|

| Receiving | 5-10% | High (unloading, counting) | Forklifts, pallet jacks, dock plates | Inbound trucks → staging |

| QC/Inspection | 2-5% | High (verification, testing) | Inspection tables, scales, scanners | Receiving → storage/hold |

| Bulk Storage | 60-80% | Low (full pallet moves) | Forklifts, reach trucks, VNA equipment | Receiving → long-term hold → replenishment |

| Forward Pick | 10-20% | Very high (case/each picking) | Order pickers, carts, pick-to-light | Replenishment → order fulfillment |

| Packing | 3-8% | High (verification, packaging) | Pack stations, scales, label printers | Picked items → packed orders |

| Shipping | 5-10% | High (sorting, loading) | Forklifts, conveyors, sortation | Packed orders → outbound trucks |

| Returns | 2-5% | High (inspection, disposition) | Tables, scanners, repack stations | Customer returns → disposition |

These percentages are guidelines and vary significantly based on operation type. E-commerce fulfillment centers may allocate more space to forward pick and packing zones, while bulk distribution centers prioritize reserve storage.

Zone Layout Principles

Effective zone design follows several core principles:

1. Flow Pattern Alignment

Zones should be arranged to support a linear or U-shaped flow that minimizes backtracking and cross-traffic. Common layouts include:

- I-shaped (through-flow) — Receiving on one end, shipping on the other, with storage and picking in between

- U-shaped — Receiving and shipping on the same wall, with storage forming a "U" around the picking area

- L-shaped — Receiving and shipping on adjacent walls, common in existing buildings with limited dock access

2. Activity-Based Positioning

High-activity zones (picking, packing) should be centrally located to minimize travel distance from all other zones. Low-activity zones (bulk storage of slow-movers) can be positioned in deeper or less accessible areas.

3. Scalability and Flexibility

Zone boundaries should allow for seasonal expansion or operational shifts. Temporary zones (e.g., holiday overflow storage) can be carved from staging areas or converted from underutilized space.

4. Safety and Traffic Control

- Separate pedestrian and forklift traffic wherever possible

- Use designated aisles and floor markings to control flow

- Position heavy equipment zones (bulk storage) away from high-touch areas (packing stations)

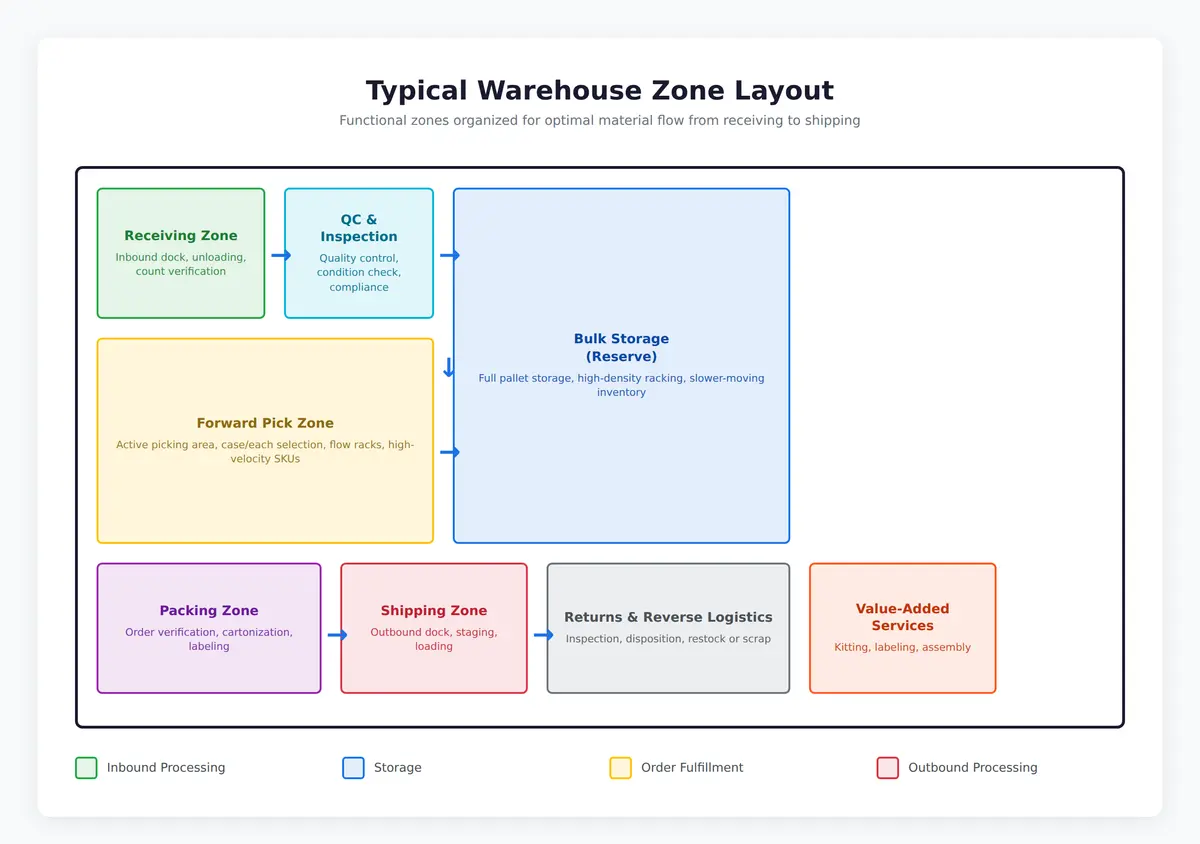

Typical Warehouse Zone Layout

The following diagram shows a standard warehouse layout with all major functional zones positioned for optimal material flow:

This layout represents a U-shaped flow pattern where receiving and shipping are positioned on the same side of the building, allowing for efficient staging and cross-dock operations when needed. The forward pick zone is centrally located to minimize travel distance from bulk storage and to packing stations.

Goods Flow Through Zones

The following diagram illustrates the process flow from receiving through shipping:

This flow represents a standard put-away and pick operation. Cross-docking facilities bypass bulk storage entirely, moving goods directly from receiving to shipping. High-velocity operations may use wave picking or zone picking strategies that modify this flow to improve efficiency.

For more details on receiving and putaway workflows, see Receiving & Putaway. For picking strategies, see Picking & Packing.

Best Practices for Zone Management

- Use data to drive zone design — Analyze order profiles, SKU velocity, and throughput requirements to size zones appropriately.

- Mark zones clearly — Use floor tape, signage, and location labels to define zone boundaries and guide workers.

- Monitor zone utilization — Track space usage and adjust zone allocations based on seasonal demand or operational changes.

- Maintain buffer space — Reserve 10-15% of total space for staging, peak overflow, and operational flexibility.

- Review and optimize regularly — Warehouse operations evolve; conduct quarterly or annual reviews of zone layouts and slotting assignments.

Resources

| Resource | Description | Link |

|---|---|---|

| Material Handling Industry (MHI) | Industry association providing warehouse design standards and best practices | mhi.org |

| OSHA Warehouse Safety | U.S. government guidelines for safe warehouse operations and layout | osha.gov |

| Warehouse Education and Research Council (WERC) | Research and educational resources on warehouse operations and design | werc.org |

| International Warehouse Logistics Association (IWLA) | Best practices and standards for warehouse and logistics operations | iwla.com |

Well-designed warehouse zones create a foundation for efficient operations, reducing travel time, improving throughput, and supporting scalable growth. Understanding zone functions and flow patterns is essential for any warehouse professional.