FTL vs LTL Shipping

Choosing between Full Truckload (FTL) and Less-Than-Truckload (LTL) shipping is one of the most consequential decisions in domestic freight logistics. The two modes differ fundamentally in how trailer space is allocated, how pricing is structured, how freight is handled, and how quickly it reaches its destination. Understanding these trade-offs is essential for optimizing both cost and service in any supply chain operation.

What is FTL (Full Truckload)

Full Truckload (FTL) shipping means a single shipper's freight occupies the entire trailer — or at least pays for exclusive use of it. The trailer moves directly from origin to destination without intermediate stops or transfers. FTL is the dominant mode for large-volume shipments and is served by a vast network of for-hire truckload carriers and owner-operators across North America.

Key characteristics of FTL:

- Trailer capacity: Standard dry van is 53 feet long with approximately 3,000 cubic feet of space

- Weight limit: Up to 44,000–45,000 lbs for a standard dry van (varies by axle configuration and state regulations)

- Direct routing: Point-to-point movement; no hub transfers

- Single handling: Freight is loaded once and unloaded once

- Pricing: Quoted per load (flat rate) or per mile; not dependent on freight class

FTL does not require the trailer to be physically full. A shipper may book an FTL even for 10,000 lbs if they need the speed, security, or simplicity of dedicated trailer space. You pay for the trailer, not the weight.

What is LTL (Less-Than-Truckload)

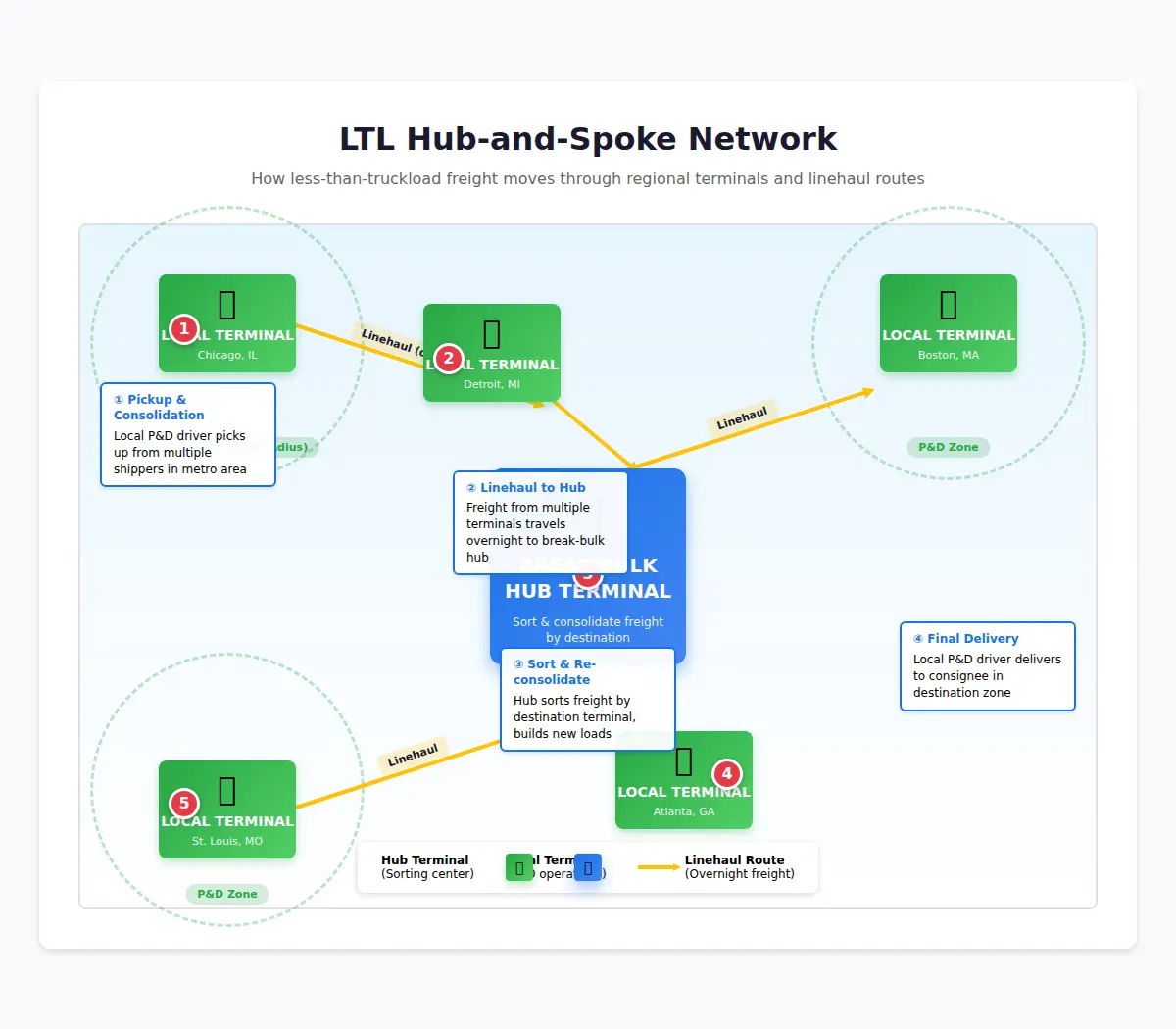

Less-Than-Truckload (LTL) shipping allows multiple shippers to share space on a single trailer. Each shipper pays only for the portion of the trailer their freight occupies. LTL carriers operate hub-and-spoke networks, consolidating freight from multiple origins at regional terminals and sorting it for delivery to various destinations.

Key characteristics of LTL:

- Shipment size: Typically 100 to 10,000 lbs (some carriers accept up to 20,000 lbs)

- Handling units: Usually palletized; counted in pallets, skids, or crates

- Multiple touches: Freight is loaded, unloaded, and reloaded at intermediate terminals

- Pricing: Based on weight, freight class, distance, and accessorials

- Transit network: Hub-and-spoke with terminal cross-docking

Detailed Comparison

| Factor | FTL | LTL |

|---|---|---|

| Shipment size | 10,000+ lbs or full trailer | 100–10,000 lbs |

| Pricing model | Per load or per mile | Per CWT by freight class + accessorials |

| Typical cost per lb | $0.02–$0.10/lb | $0.10–$0.50/lb |

| Transit time (500 mi) | 1–2 days | 3–5 days |

| Transit time (1,500 mi) | 2–4 days | 5–10 days |

| Number of handling events | 2 (load + unload) | 4–8 (pickup, terminal transfers, delivery) |

| Damage risk | Lower | Higher (more touches) |

| Trailer exclusivity | Dedicated | Shared with other shippers |

| Freight class required | No | Yes (NMFC classification) |

| Tracking granularity | GPS on trailer | Terminal scans at each hub |

| Common accessorials | Detention, TONU | Liftgate, inside delivery, limited access, reclass |

| Carrier network | Truckload carriers, brokers | LTL carriers (ODFL, XPO, Estes, FedEx Freight, Saia) |

Pricing Deep Dive

FTL Pricing

FTL rates are driven primarily by:

- Lane and distance: Market rate for the origin-destination pair

- Supply and demand: Carrier availability in the origin market (headhaul vs. backhaul)

- Equipment type: Dry van, refrigerated, flatbed, specialized

- Fuel surcharge: Indexed to DOE national average diesel price

- Seasonality: Produce season, peak retail, weather disruptions

FTL pricing is typically quoted as a flat rate per load or a rate per mile. The national average truckload rate (dry van) fluctuates between $1.50 and $3.50 per mile depending on market conditions, with the fuel surcharge as an additional line item.

LTL Pricing

LTL pricing is significantly more complex, based on:

- Weight: Total shipment weight in pounds

- Freight class: NMFC classification from 50 (least expensive) to 500 (most expensive); see Freight Classes

- Distance: Origin-to-destination zip code pair

- Discount from tariff: LTL carriers publish base tariffs (e.g., CZAR-Lite) and offer percentage discounts (60–85% off tariff is common for volume shippers)

- Accessorial charges: Liftgate delivery, residential delivery, limited-access pickup, inside delivery, notification/appointment, reweigh/reclass fees

- Density: Increasingly, carriers use density-based pricing or dimensional weight to prevent low-density freight from consuming disproportionate trailer space

LTL carriers routinely reweigh and reclassify shipments at their terminals. If the actual weight or dimensions differ from the BOL, the carrier will issue an adjusted invoice — often substantially higher. Accurate Bill of Lading data is your best defense against surprise charges.

When to Use Each Mode

Choose FTL When

- Shipment weight exceeds 10,000 lbs (or approximately 6+ pallets of dense freight)

- Time-sensitive delivery is required (1–2 day transit)

- Cargo is fragile or high-value and cannot tolerate multiple handling events

- You are shipping hazardous materials that require dedicated equipment

- The per-unit cost of LTL approaches or exceeds the cost of a full truck (the break-even point)

Choose LTL When

- Shipment weight is under 10,000 lbs (1–6 pallets)

- Transit time of 3–7 days is acceptable

- Budget is a primary constraint and you need to share trailer cost with other shippers

- Freight is durable and palletized, able to withstand terminal handling

- You ship regularly but in small quantities that don't justify a full truck

The Break-Even Calculation

A critical skill in freight logistics is identifying the FTL/LTL break-even point — the weight at which booking a full truck becomes cheaper than paying LTL rates.

For most freight classes and lanes, the break-even point falls between 8,000 and 12,000 lbs. Above this range, request both LTL and FTL quotes and compare. A 10,000 lb LTL shipment of Class 125 freight on a 1,000-mile lane can easily cost $3,000–$5,000, while an FTL on the same lane might cost $2,500–$3,500.

Partial Truckload (PTL): The Middle Ground

Partial Truckload (PTL) — sometimes called volume LTL — occupies the space between traditional LTL and FTL. PTL shipments typically weigh 8,000–30,000 lbs or occupy 6–18 linear feet of trailer space.

PTL offers a hybrid value proposition:

- Fewer handling events than LTL (often only 1–2 terminal touches)

- Lower cost per pound than standard LTL for heavy shipments

- No freight class required — many PTL carriers price on weight and linear feet only

- Faster transit than LTL due to fewer terminal transfers

| Attribute | LTL | PTL | FTL |

|---|---|---|---|

| Weight range | 100–10,000 lbs | 8,000–30,000 lbs | 10,000–45,000 lbs |

| Pricing basis | Class + weight | Weight + linear feet | Per load / per mile |

| Handling events | 4–8 | 2–4 | 2 |

| Transit time | 3–10 days | 2–5 days | 1–4 days |

| Freight class needed | Yes | Usually no | No |

Practical Decision Framework

Resources

| Resource | Description |

|---|---|

| FMCSA Size and Weight Regulations | Federal truck size and weight limits |

| NMFTA — Freight Classification | Official NMFC freight class lookup and standards |

| DOE Weekly Diesel Prices | National average diesel fuel prices used for fuel surcharges |

| SMC³ — LTL Tariff Data | Industry-standard LTL base rate and benchmark tariffs |

| FHWA Freight Analysis Framework | Federal data on U.S. freight flows by mode and commodity |