EPCIS 2.0 Sensor Reports: The Missing Link in Cross-Party Supply Chain Traceability

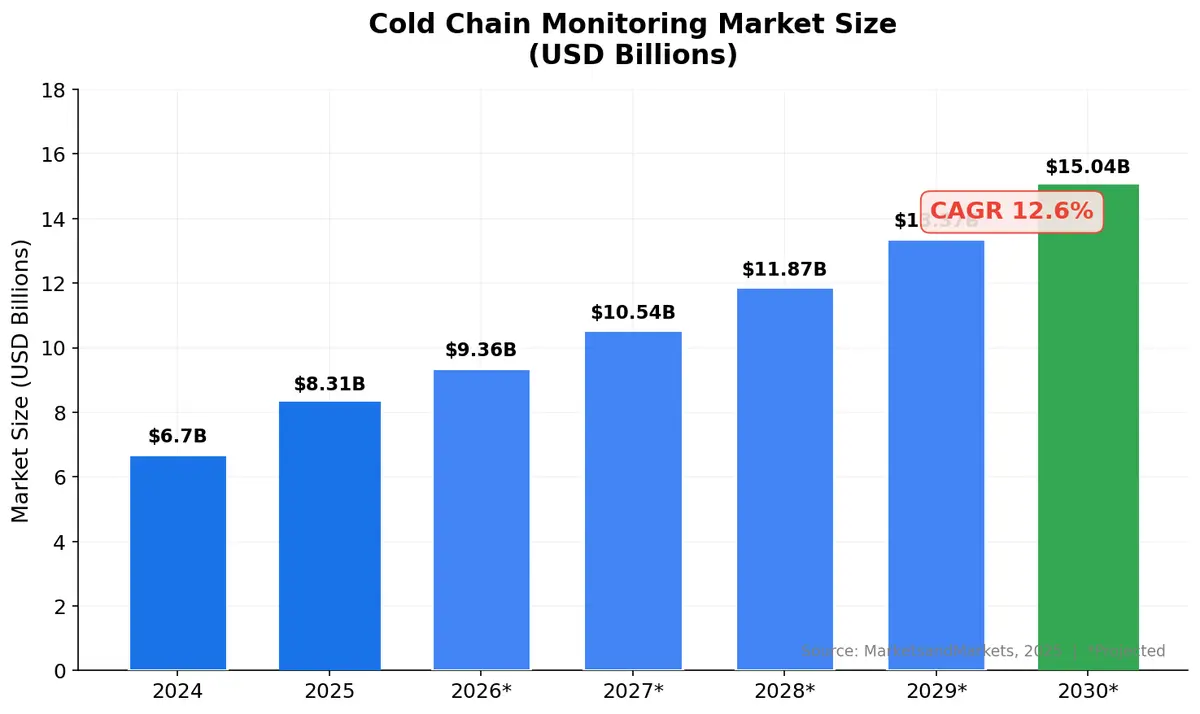

With the global cold chain monitoring market projected to reach $15 billion by 2030 — nearly double its 2025 valuation of $8.3 billion — the logistics industry's appetite for continuous, standardized sensor data has never been greater. Yet most supply chains still suffer from a critical blind spot: sensor readings captured by one trading partner remain locked in proprietary silos, invisible to everyone else in the chain. EPCIS 2.0, the latest evolution of GS1's Electronic Product Code Information Services standard, directly addresses this gap with its new sensor-report capability.

What Is EPCIS and Why Does 2.0 Matter?

EPCIS has been the backbone of supply chain event data since version 1.0 launched in 2007. At its core, the standard answers four questions about every supply chain event: what happened, when it happened, where it happened, and why it happened. Trading partners use EPCIS to record everything from manufacturing and packing to shipping and receiving — creating a shared, interoperable record of a product's journey.

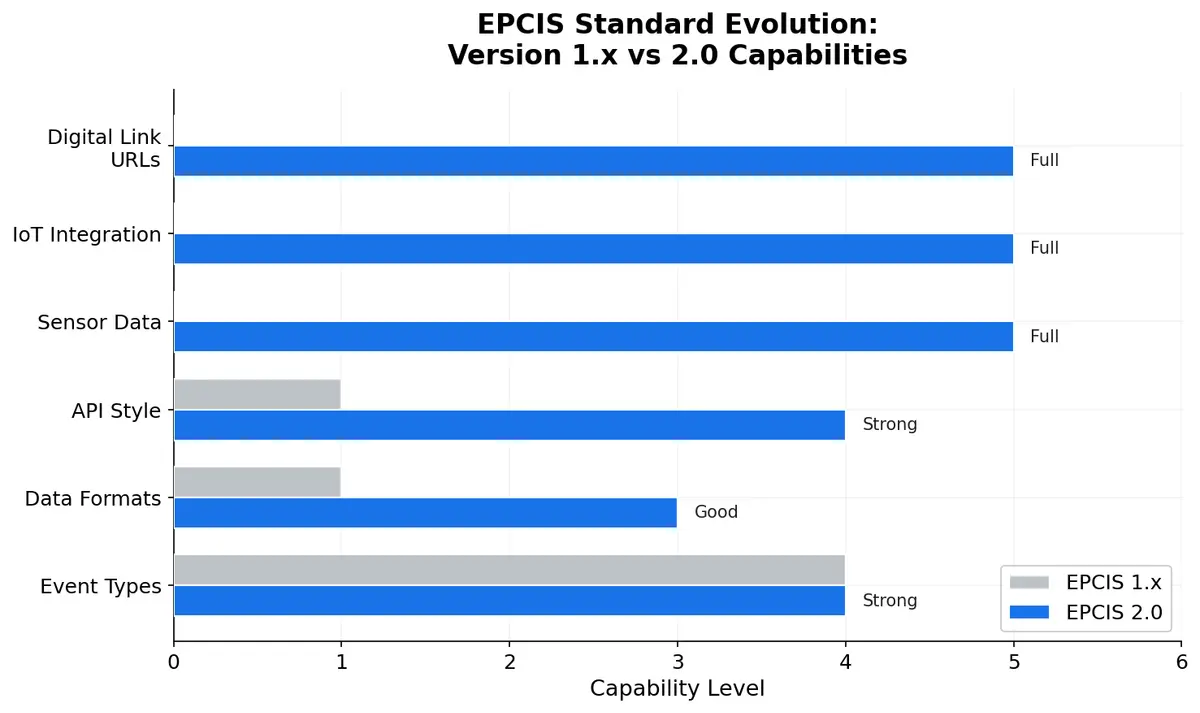

Version 2.0, ratified by GS1 after more than four years of collaborative development, represents a fundamental modernization. It introduces a RESTful Web API with JSON and JSON-LD payloads, compatibility with GS1 Digital Link URLs, and — most significantly for logistics operators — native support for IoT sensor data embedded directly within supply chain events.

Where EPCIS 1.x could only tell you that a pallet arrived at a warehouse, EPCIS 2.0 can tell you the exact temperature, humidity, and light exposure that pallet experienced during transit — and share that data seamlessly with every authorized partner in the chain.

The Sensor-Report Element: A Fifth Dimension

Traditional EPCIS events capture the "what, where, when, and why" of supply chain activity. EPCIS 2.0 adds a fifth dimension: how — the physical conditions under which events occur. This is accomplished through the sensorElement and sensorReport data structures.

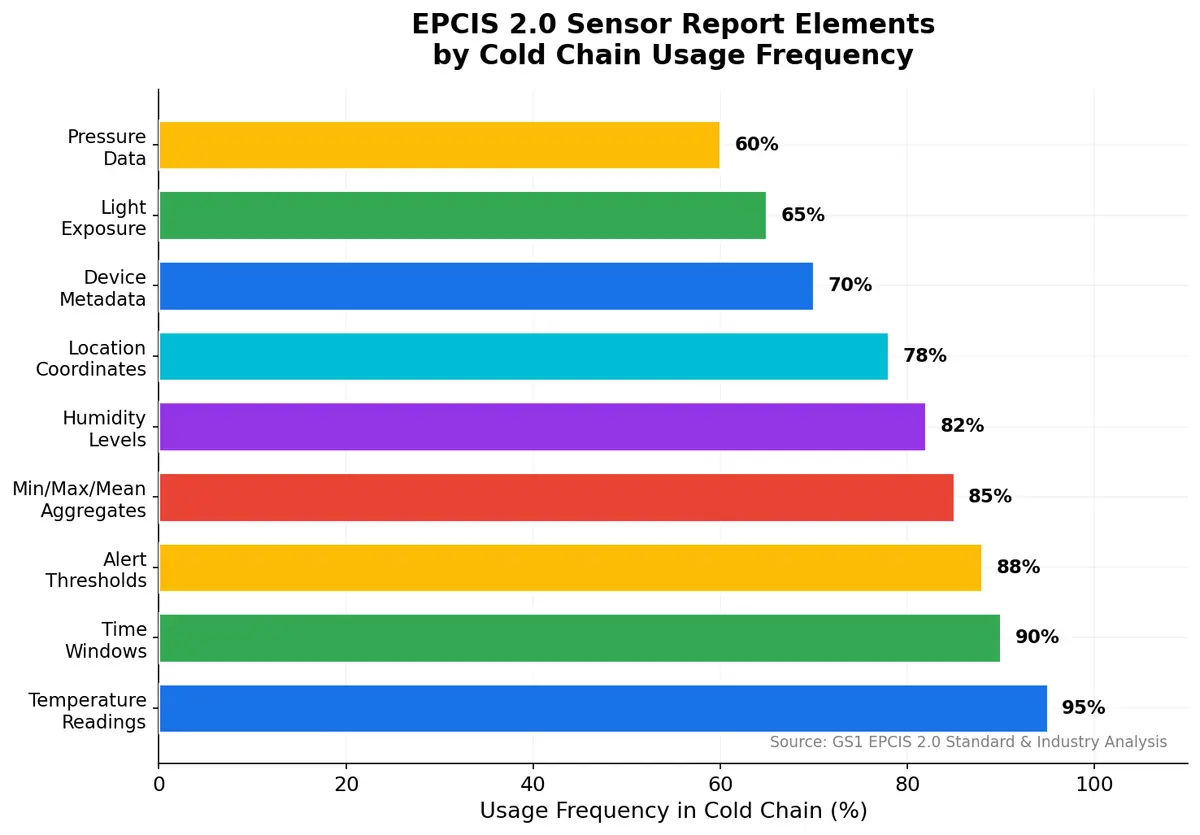

A sensor report can be attached to any EPCIS event and includes:

- Measurement type — temperature, humidity, pressure, illumination, speed, or any GS1-recognized sensor property

- Value and unit — the actual reading (e.g., -18.2°C) with standardized units of measure

- Time window — start and end timestamps showing exactly when the measurement was taken

- Min/max/mean values — aggregated readings over a time period, not just point-in-time snapshots

- Device metadata — identification of the sensor device, calibration info, and reporting thresholds

- Alert conditions — boolean flags indicating whether readings exceeded defined thresholds

This means a single EPCIS "receiving" event at a distribution center can carry the complete temperature history from the moment a shipment left the origin facility. No separate data exports, no proprietary integrations, no manual reconciliation.

Why Cross-Party Traceability Changes Everything

The real power of EPCIS 2.0 sensor reports lies in cross-party interoperability. Today, a pharmaceutical manufacturer might use one IoT platform to monitor cold chain conditions, while their 3PL uses another, and the receiving hospital uses a third. Each system captures valuable data, but sharing it requires custom integrations that are expensive to build and fragile to maintain.

With EPCIS 2.0, sensor data follows the same standardized format regardless of who captured it. When a vaccine shipment moves from manufacturer to distributor to hospital, each party appends sensor reports to EPCIS events using the same schema. The result is an unbroken chain of custody and condition data that any EPCIS-compliant system can read.

As Supply Chain Dive reports, EPCIS-based traceability frameworks are rapidly becoming the foundation for scope 3 reporting and regulatory compliance across global supply chains.

This capability addresses several critical industry challenges:

Regulatory Compliance at Scale

The FDA's Food Safety Modernization Act (FSMA) Rule 204, the EU's Falsified Medicines Directive, and similar regulations worldwide demand end-to-end traceability with condition monitoring. EPCIS 2.0 sensor reports provide a standards-based way to demonstrate compliance across organizational boundaries — without locking into any single vendor's platform.

Dispute Resolution

Temperature excursions during transit are a leading cause of claims and disputes in cold chain logistics. When sensor data is embedded in standardized EPCIS events with precise timestamps and location data, determining exactly where and when a breach occurred — and who was responsible — becomes straightforward rather than adversarial.

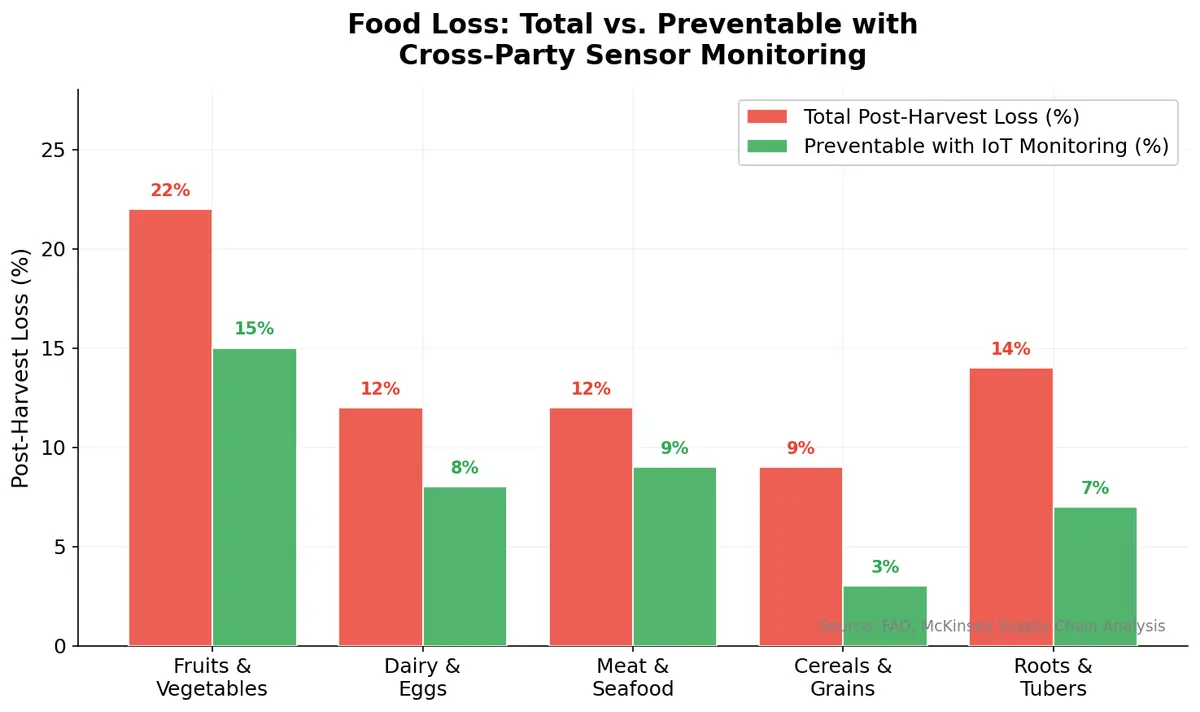

Sustainability and Waste Reduction

The UN estimates that roughly 14% of food produced globally is lost between harvest and retail. Much of this loss stems from cold chain failures that go undetected because sensor data doesn't flow between trading partners. Continuous, cross-party sensor monitoring enabled by EPCIS 2.0 allows proactive intervention before spoilage occurs.

Real-World Adoption Is Accelerating

The standard is already moving from specification to implementation. The Australian Table Grapes Association (ATGA) deployed EPCIS 2.0 with GS1 Digital Link QR codes, enabling consumers to access provenance information — including IoT temperature logging — for individual grape shipments. In the EU, EPCIS 2.0 is being leveraged for Digital Product Passport initiatives that require lifecycle traceability including environmental condition data.

Open-source toolkits like EPCIS2.js — developed collaboratively with Zebra Technologies — are lowering the barrier to adoption by providing ready-made libraries for building web applications that capture and consume EPCIS 2.0 events, including sensor reports.

The IoT cold chain monitoring market itself is growing at a compound annual rate exceeding 12%, reflecting the urgency across food, pharmaceutical, and chemical logistics to digitize condition monitoring. EPCIS 2.0 provides the standardized backbone that prevents this sensor data from becoming yet another set of isolated silos.

What This Means for TMS and Logistics Platforms

For transportation management systems and logistics platforms, EPCIS 2.0 sensor-report support is becoming a competitive differentiator. Shippers and carriers that can ingest, generate, and share EPCIS 2.0 events — including sensor data — position themselves as preferred partners for industries where condition monitoring is non-negotiable.

Key implementation considerations include:

- API-first architecture — EPCIS 2.0's RESTful API with JSON payloads integrates naturally with modern TMS platforms

- Event-driven processing — sensor reports can trigger automated workflows (rerouting, alerts, quality holds) in real time

- Multi-party visibility — a single EPCIS repository can serve as the shared truth layer for all trading partners on a shipment

- Backward compatibility — EPCIS 2.0 remains compatible with 1.x implementations, allowing gradual migration

The Standard Is Ready. Is Your Supply Chain?

EPCIS 2.0 isn't a future promise — it's a ratified, deployed standard with growing ecosystem support. The sensor-report capability transforms what was purely an event-tracking standard into a comprehensive visibility platform that spans organizations, geographies, and technology stacks. For logistics operators still relying on proprietary sensor platforms and manual data sharing, the cost of waiting is measured in compliance risk, spoilage losses, and competitive disadvantage.

Ready to integrate EPCIS 2.0 traceability into your logistics operations? Contact CXTMS for a demo.