Dark Warehouses Are Here: How Lights-Out Fulfillment Is Cutting Costs 40% While Running 24/7

The lights are off—and that's exactly the point. A new generation of fully autonomous warehouses is operating around the clock without a single human on the floor, slashing energy costs, eliminating labor constraints, and redefining what throughput looks like in 2026.

What Is a Dark Warehouse?

A "dark warehouse" (also called a lights-out facility) is a distribution center designed to operate entirely without human presence. No overhead lighting. No climate control for human comfort. No break rooms, parking lots, or safety signage. Every function—from receiving and putaway to picking, packing, and shipping—is handled by autonomous systems.

The concept isn't new, but the enabling technology has finally caught up.

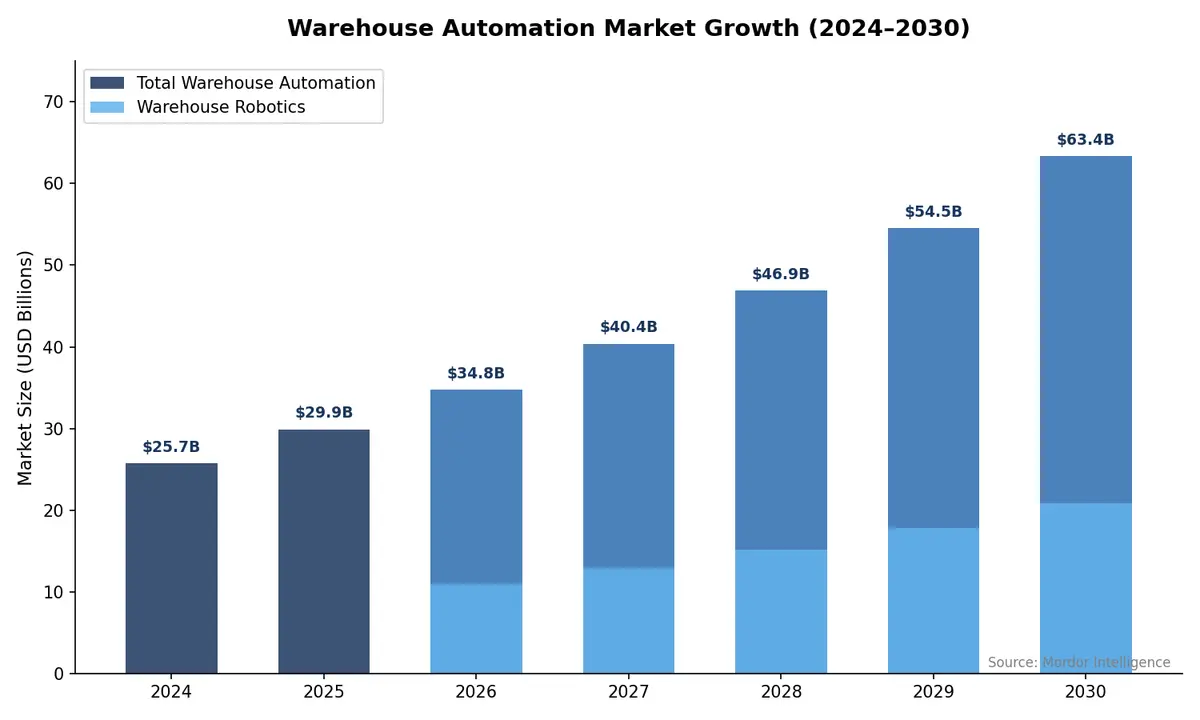

The warehouse automation market is projected to reach USD 29.91 billion in 2025 and grow at a 16.2% CAGR to USD 63.36 billion by 2030, according to Mordor Intelligence. Within that surge, the warehouse robotics segment alone is valued at USD 10.96 billion in 2026, growing at 17.5% annually.

Current Deployments: From Ocado to Corvus Robotics

The most visible example of near-dark warehouse operations is Ocado's Customer Fulfillment Centers (CFCs). These grid-based systems use thousands of bots moving across a massive 3D grid to retrieve grocery totes, achieving pick rates that dwarf conventional operations. Mark Richardson, CEO of Ocado Intelligent Automation, has noted that the steady march toward increased automation is accelerating, even among low-cost operations that never previously considered it.

Meanwhile, Corvus Robotics has deployed fully autonomous drone systems that scan warehouse inventory in complete darkness—no human operators required. Their drones navigate using onboard sensors and AI vision, performing cycle counts at 3–5x the speed of manual methods with 99.5% accuracy.

On the floor level, autonomous mobile robots (AMRs) now operate as swarm intelligence systems, dynamically re-slotting inventory based on real-time demand signals. If a product goes viral on social media, AMR swarms can reposition high-velocity SKUs closer to packing stations within minutes—something no human workforce could coordinate at scale.

The Cost Breakdown: Where 40% Savings Come From

The economics of dark warehouses are compelling across multiple cost categories:

Energy Savings (25–35%)

Without humans, there's no need for lighting, heating, or air conditioning. Industrial HVAC systems typically account for 30–40% of a warehouse's energy bill. Dark facilities eliminate this entirely, maintaining only the minimal temperature range required by the products themselves. LED indicators on robots consume a fraction of the energy of full facility lighting.

Labor Elimination (40–60%)

Labor remains the single largest warehouse operating cost, typically representing 50–70% of total facility expenses. Dark warehouses reduce this to near zero for floor operations, retaining only a small remote monitoring team and maintenance technicians who visit periodically. In a market where warehouse labor turnover exceeds 40% annually, removing the dependency on human staffing eliminates recruitment, training, and retention costs entirely.

24/7 Throughput Without Shift Premiums

Autonomous systems don't take breaks, call in sick, or require overtime pay. A dark warehouse operates continuously at peak efficiency—three full shifts at consistent speed without the productivity drop-offs typical of late-night human shifts. Facilities report 2.5–3x throughput increases compared to equivalent manually operated warehouses.

Reduced Error and Returns Costs

Machine vision picking systems reduce error rates to near-zero levels. Given that pick-and-pack errors drive a significant portion of reverse logistics costs, the savings cascade through the entire fulfillment chain. Fewer errors mean fewer returns, less customer service overhead, and higher customer satisfaction scores.

When Dark Warehouses Make Sense—and When They Don't

Lights-out fulfillment isn't universal. It works best for:

- High-volume, predictable SKU profiles — standardized products with consistent dimensions

- E-commerce fulfillment centers — where speed and accuracy are paramount

- Cold storage and hazardous environments — where removing humans improves safety and reduces HVAC costs even further

- Grocery micro-fulfillment — Ocado-style CFCs handling thousands of daily orders

It's still impractical for:

- Highly variable or fragile goods requiring human judgment for handling

- Low-volume, high-mix operations where the automation investment can't be justified

- Returns processing — the unstructured nature of returned goods remains a challenge for robots

As Richardson noted, completely human-free operations at broad scale "are still a little bit away from us." The pragmatic approach in 2026 is hybrid automation: lights-out zones for standardized processes, with human-staffed areas for exceptions and complex tasks.

Connecting Dark Warehouses to Your Supply Chain

The most sophisticated dark warehouse is only as effective as its integration with upstream and downstream systems. Real-time data feeds between warehouse management systems (WMS) and transportation management platforms are critical for synchronizing autonomous fulfillment with carrier pickups, demand planning, and inventory replenishment.

CXTMS integrates with lights-out WMS feeds to provide end-to-end visibility from autonomous picking through final-mile delivery. When a dark warehouse completes an order in minutes rather than hours, the transportation layer needs to keep pace—dynamic carrier selection, real-time dock scheduling, and automated shipment consolidation become essential.

The Bottom Line

Dark warehouses aren't science fiction—they're operational reality in 2026 for the right use cases. With the warehouse automation market on track to more than double by 2030 and robotics costs continuing to decline, the question for logistics leaders isn't whether to automate, but how quickly to move toward lights-out operations in their highest-volume facilities.

The 40% cost reduction is real. The 24/7 uptime is proven. The competitive advantage is compounding.

Ready to connect your automated warehouses with intelligent transportation management? Contact CXTMS for a demo and see how real-time WMS integration transforms your fulfillment operations.