The AI Operating Layer Has Arrived: Why Supply Chain Copilots Are Replacing Standalone Analytics Tools

A year ago, AI in supply chain meant chatbots answering "where's my shipment?" and generative models summarizing weekly reports. Useful, but incremental. In 2026, the game has shifted entirely — AI is no longer a bolt-on analytics tool sitting beside your TMS. It's becoming the operating layer that connects procurement, logistics, finance, and customer service into a single decision-execution fabric.

From Dashboards to Doing: What the AI Operating Layer Actually Is

The concept is straightforward but the implications are massive. Instead of logging into separate analytics platforms to review freight spend, carrier performance, or inventory levels, an AI copilot embedded directly in your TMS or ERP monitors all of these data streams simultaneously — and acts on them.

According to Logistics Viewpoints, these AI agents can now "execute multi-step workflows autonomously, coordinating across systems, making decisions based on real-time data, and acting on those decisions without waiting for a human to click approve." They read shipping documents, cross-reference contracted rates, flag discrepancies, and initiate dispute processes — continuously, across thousands of transactions per week.

This isn't science fiction. Gartner predicted that by 2026, more than 80% of enterprises would have deployed generative AI-enabled applications in production environments, up from less than 5% in early 2023. That prediction has largely materialized — and supply chain is one of the fastest-adopting verticals.

Collapsing the Silos That Have Defined Logistics for Decades

Here's the core insight: supply chain data is the connective tissue between departments that have historically operated as if they had nothing to do with each other.

Finance needs delivery confirmation to trigger early payment discounts. Procurement needs carrier performance data for scorecards. Customer service needs real-time order status to handle penalty claims. Production planning needs inbound ETAs to adjust manufacturing schedules.

All of these decisions happen in different departments, in different systems, managed by different teams. But they all start with the same data — shipments, orders, inventory, and deliveries.

For years, the handoffs between "supply chain knows something" and "another department acts on it" have been painfully manual. Someone pulls a report. Someone else verifies it. A third person takes action in a different system. An AI operating layer eliminates those handoffs entirely. A delayed inbound shipment doesn't wait for someone to notice it in a morning report — the agent detects the delay, recalculates the dock schedule, and notifies the facility team before anyone opens a spreadsheet.

Copilot vs. Autonomous Agent: The Critical Distinction

It's important to distinguish between two AI paradigms reshaping logistics in 2026:

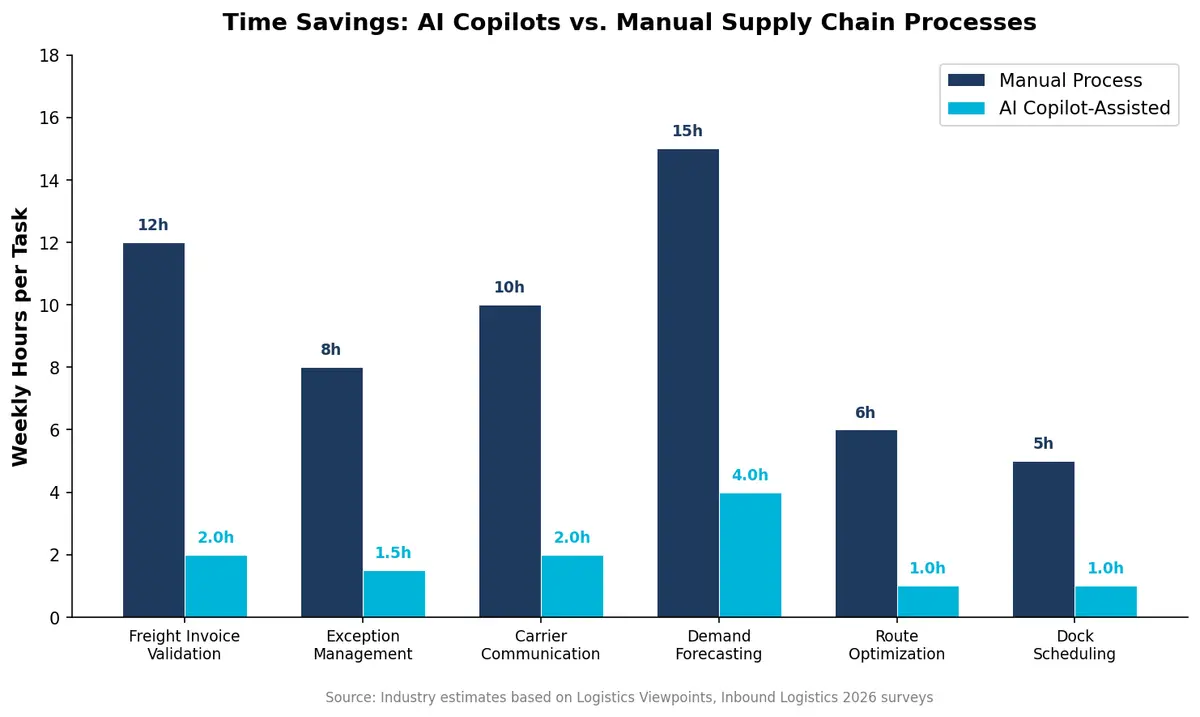

AI copilots are human-in-the-loop assistants embedded in your existing tools. They suggest route optimizations, flag invoice anomalies, draft carrier communications, and present options — but a human makes the final call. Think of them as the AI equivalent of a highly competent analyst sitting beside every logistics planner.

Agentic AI operates autonomously, executing end-to-end workflows without human intervention. According to Inbound Logistics' 2026 outlook, industry leaders rated AI's expected usefulness in supply chain management at an average of 8 out of 10, with DHL's VP of Analytics noting that "agentic AI will automate routine communication to improve efficiency" while "AI-driven computer vision will help warehouses process goods faster, reduce errors, and optimize space utilization."

The AI operating layer encompasses both. For high-stakes decisions — carrier contract negotiations, mode shifts, customer commitments — copilots keep humans in control. For high-volume, rules-based tasks — freight invoice validation, appointment scheduling, exception alerting — agents handle it autonomously.

What This Means for Your Tech Stack

The practical implication for shippers is significant: standalone analytics tools that require you to export data, build reports, and then manually act on insights are being absorbed into AI-native platforms.

Microsoft, Google Cloud, and Oracle are all embedding generative copilots directly into their supply chain management suites. Microsoft's Copilot in Dynamics 365 Supply Chain Management can now surface demand anomalies, suggest inventory rebalancing, and draft supplier communications — all within the same interface where planners do their daily work.

This convergence means the traditional "best-of-breed analytics" approach is being challenged. Why pay for a separate freight analytics tool when your TMS copilot can analyze spend patterns, benchmark rates, and recommend optimization strategies in real time?

The answer, for now, is depth. Specialized tools still offer deeper analytical capabilities in specific domains. But the gap is closing rapidly, and for mid-market shippers who can't afford a dozen point solutions, the embedded copilot approach offers 80% of the value at a fraction of the cost and complexity.

The Adoption Reality Check

Despite the momentum, supply chain AI adoption isn't uniform. Organizations with clean, connected data are seeing transformative results. Those still running on fragmented spreadsheets and siloed ERPs are struggling to get basic AI features working.

The prerequisite for an AI operating layer is data infrastructure. You need real-time shipment visibility, standardized carrier data feeds, and integrated financial and operational systems. Without that foundation, even the most sophisticated AI copilot has nothing meaningful to work with.

This is where TMS platforms become critical — not just as transportation management tools, but as the data backbone that enables AI capabilities across the supply chain.

Building the AI-Ready Supply Chain with CXTMS

CXTMS is purpose-built for this new paradigm. By centralizing shipment data, carrier performance metrics, financial reconciliation, and customer delivery requirements in a single platform, CXTMS provides the unified data layer that AI copilots need to deliver real value.

From automated freight invoice validation to intelligent exception management and predictive ETA adjustments, CXTMS is embedding AI capabilities directly into the workflows logistics teams use every day — not as a separate analytics module, but as an integrated operating layer that makes every team member more effective.

Ready to build your AI-powered supply chain operating layer? Contact CXTMS for a demo and see how embedded AI copilots can transform your logistics operations.