AI Inventory Optimization Goes Autonomous: How Cognitive Replenishment Is Replacing Safety Stock Formulas in 2026

For decades, inventory managers have relied on the same fundamental tool: the safety stock formula. Calculate average demand, estimate lead time variability, multiply by a service level factor, and hope for the best. In a world of predictable supply chains, it worked well enough. In 2026, it's a liability.

The Problem With Static Safety Stock

Traditional safety stock calculations assume that demand follows predictable patterns and that lead times remain relatively stable. But post-pandemic supply chains have shattered those assumptions. Geopolitical disruptions, climate-driven logistics delays, and rapidly shifting consumer preferences mean that a safety stock number calculated last quarter may be dangerously wrong today.

The result is a painful paradox: companies simultaneously carry too much of the wrong inventory and too little of the right inventory. According to McKinsey, AI can reduce inventory levels by 20 to 30 percent by improving demand forecasting through dynamic segmentation and machine learning — yet most organizations still rely on spreadsheet-driven min/max formulas that haven't fundamentally changed in thirty years.

What Cognitive Replenishment Actually Means

Cognitive replenishment represents a shift from reactive calculation to proactive sensing. Instead of periodically recalculating reorder points based on historical averages, AI-driven systems continuously ingest signals from multiple channels — point-of-sale data, weather forecasts, social media trends, supplier lead time fluctuations, even competitor pricing changes — to make autonomous replenishment decisions in real time.

The key distinction is autonomy. Traditional demand planning produces a forecast that humans review and adjust. Cognitive replenishment systems can execute purchasing and allocation decisions within predefined guardrails, intervening only when conditions fall outside expected parameters. Gartner predicts that by 2030, half of all supply chain management solutions will include agentic AI capabilities — and autonomous inventory replenishment is the leading use case.

From Single-Node to Multi-Echelon Optimization

One of the most significant advances in AI-driven inventory management is multi-echelon inventory optimization (MEIO). Traditional approaches optimize each node in the supply chain independently: a warehouse sets its own safety stock, a distribution center sets its own, and a retail location sets its own. Each node buffers against uncertainty independently, which means the total system carries far more inventory than necessary.

MEIO treats the entire supply chain network as an interconnected system. AI algorithms determine the optimal placement and quantity of inventory across all echelons simultaneously, considering factors like:

- Transportation costs between nodes

- Service level requirements at each customer-facing point

- Lead time variability at each stage

- Demand correlation across locations

- Holding costs that vary by facility type

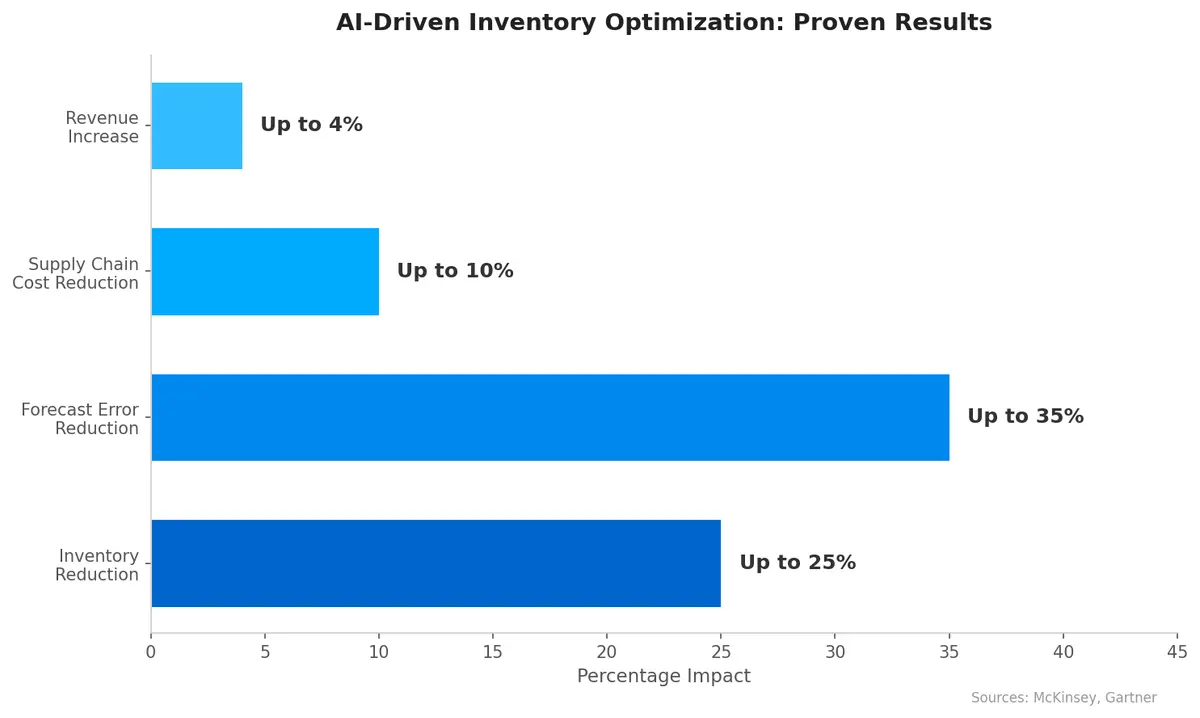

McKinsey research on autonomous supply chain planning shows that major CPG companies implementing these approaches have achieved up to 20 percent inventory reduction while simultaneously increasing revenue by up to 4 percent and decreasing supply chain costs by up to 10 percent. The gains come not from carrying less inventory everywhere, but from carrying the right inventory in the right places.

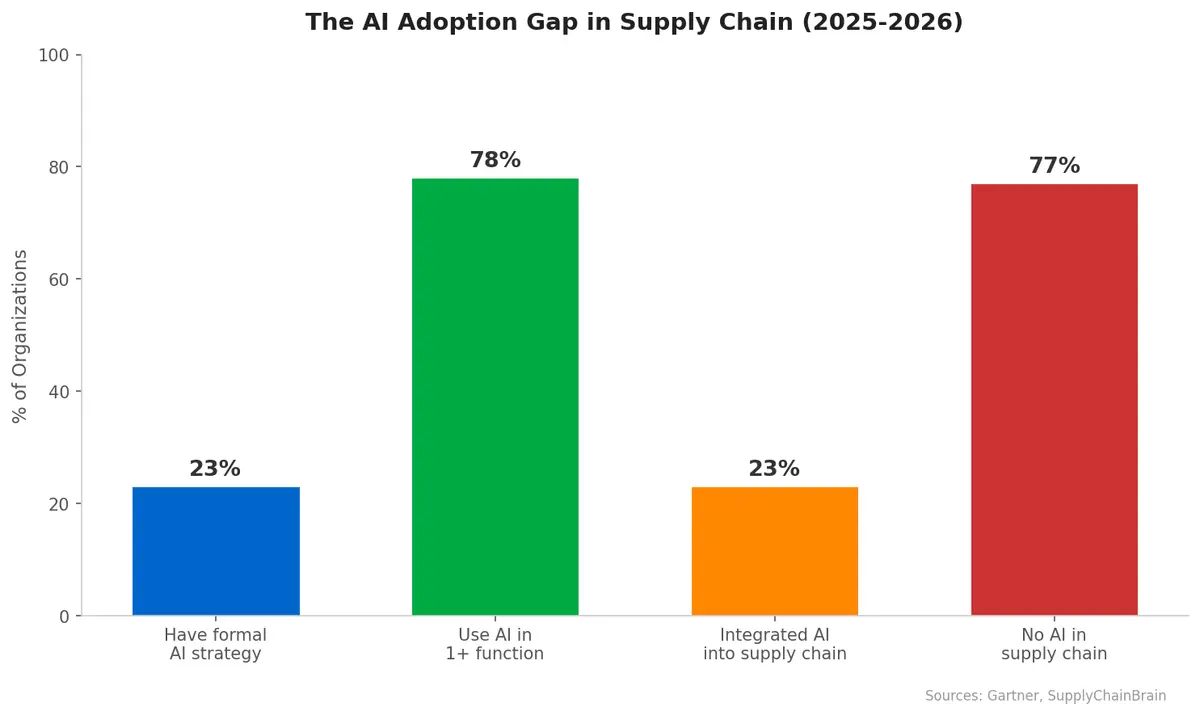

Why Only 23% Have a Strategy

Despite the compelling ROI, adoption remains uneven. A Gartner survey found that just 23 percent of supply chain organizations have a formal AI strategy in place. Meanwhile, SupplyChainBrain reports that 77 percent of organizations have yet to integrate AI into their supply chains at all.

The barriers are familiar: fragmented data across ERP, WMS, and TMS systems; lack of trust in algorithmic decision-making; and organizational resistance to replacing human judgment with autonomous systems. But the cost of inaction is growing. Companies still running static safety stock formulas are effectively flying blind in a market that demands real-time responsiveness.

The Deep Reinforcement Learning Frontier

The next wave of inventory optimization goes beyond traditional machine learning. Deep reinforcement learning (DRL) — the same technology behind game-playing AI systems — is now being applied to multi-echelon replenishment problems. Unlike supervised learning that requires historical "correct answers," DRL agents learn optimal policies through simulated trial and error, discovering replenishment strategies that no human planner would have designed.

Recent academic research published in late 2025 demonstrates that DRL-based approaches can handle the combinatorial complexity of multi-echelon networks with lost sales, dual sourcing, and stochastic lead times — problems that traditional optimization methods struggle to solve at scale. For logistics operators, this means AI systems that don't just replicate existing best practices but genuinely discover novel inventory strategies tailored to each network's unique constraints.

Building the Foundation for Autonomous Inventory

Organizations looking to move toward cognitive replenishment don't need to leap to full autonomy overnight. The path typically follows three stages:

-

Augmented forecasting — Use ML to improve demand forecasts while humans still make replenishment decisions. This alone can reduce forecasting errors by 20 to 50 percent.

-

Recommended actions — AI generates specific replenishment orders that planners review and approve. This builds trust while capturing most of the optimization value.

-

Autonomous execution — AI executes replenishment decisions within defined guardrails, with human oversight for exceptions. This is where the full 20-30 percent inventory reduction materializes.

The critical enabler at every stage is data integration. Cognitive replenishment systems are only as good as the demand signals they can access. Organizations need their TMS, WMS, and ERP data flowing into a unified platform where AI can detect patterns across the entire supply chain.

How CXTMS Connects the Dots

CXTMS bridges the gap between transportation execution and inventory intelligence. By connecting demand signals from order management to fulfillment execution across carriers and warehouses, CXTMS provides the real-time visibility layer that cognitive replenishment systems need to make informed decisions. When your TMS knows that a critical shipment is delayed before your inventory system does, you can trigger alternative sourcing or allocation changes proactively — not reactively.

The shift from static formulas to cognitive replenishment isn't optional for companies competing in volatile markets. The question isn't whether to adopt AI-driven inventory optimization, but how quickly you can build the data foundation to support it.

Ready to connect your logistics data for smarter inventory decisions? Contact CXTMS for a demo.