Why 50% of Supply Chain Leaders Still Lack End-to-End Visibility — And What the Top Performers Do Differently

Supply chain disruptions now cost businesses up to 45% of a year's profit over a decade, according to McKinsey. Yet only 6% of organizations report having full end-to-end supply chain visibility. That's not a technology problem — it's an integration problem. And in 2026, the gap between companies that can see their supply chain and those flying blind is widening into a competitive chasm.

The Visibility Paradox: Everyone Wants It, Few Have It

The numbers paint a stark picture. According to industry research, supply chain professionals ranked visibility as the number one trend ahead of diversification, cybersecurity, and ecommerce. Between 2019 and 2023, more than 5,500 patents were filed for supply chain visibility technologies alone.

Yet despite this massive investment in visibility solutions, approximately 45% of executives surveyed by McKinsey report having no visibility beyond their first-tier suppliers. And 76% of European shippers reported supply chain disruptions during 2024, with a quarter encountering more than 20 disruptive events in a single year.

The paradox is clear: companies know visibility matters, they're spending on it, but most still can't see past the first link in their chain.

Why the Gap Persists: The Integration Problem

The root cause isn't a shortage of tracking tools or sensors. It's fragmented systems that don't talk to each other.

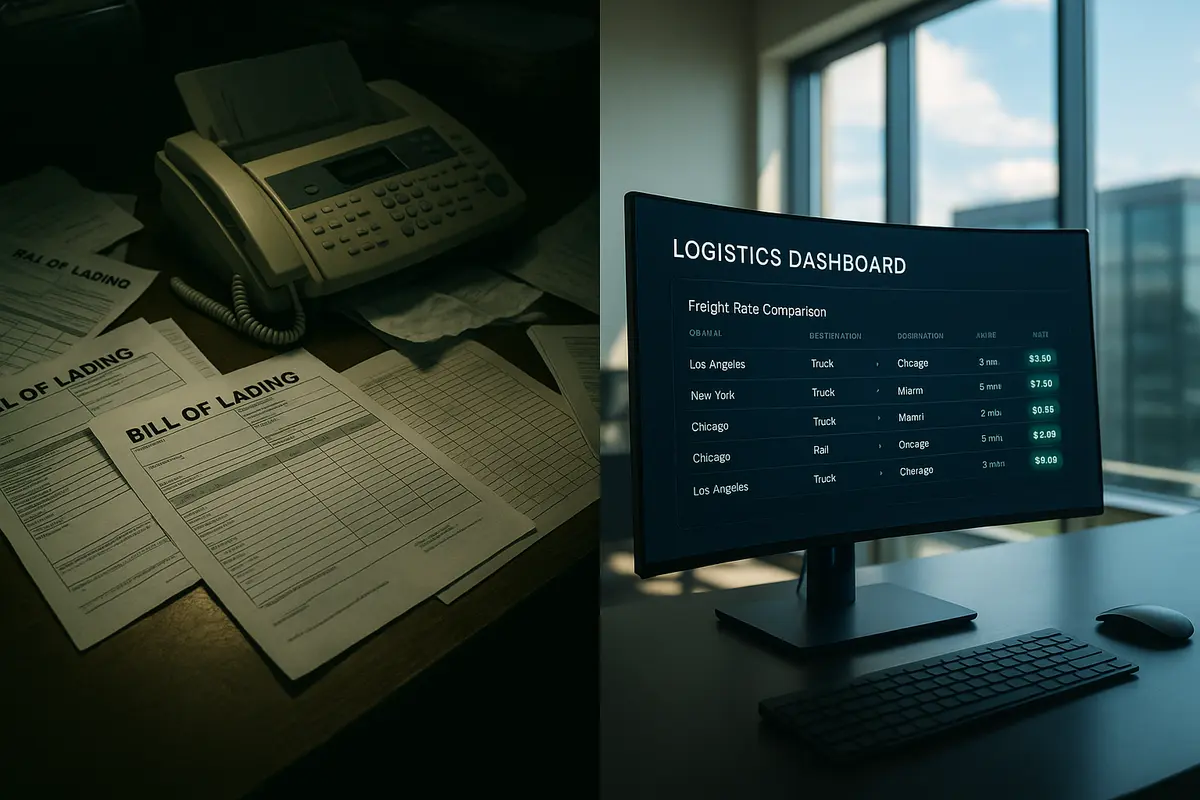

Most logistics operations run on a patchwork of carrier portals, spreadsheets, EDI connections, and siloed software platforms. Each system captures a slice of the picture — ocean carrier tracking here, warehouse management there, customs documentation somewhere else. But stitching those slices into a coherent, real-time view across the entire shipment lifecycle? That's where most organizations fall apart.

Three core barriers keep companies stuck:

-

Data silos across modes and partners. A single international shipment might touch five or more systems across ocean, rail, truck, and warehouse operations. When each system speaks a different data language, real-time consolidation becomes nearly impossible.

-

Tier 1 tunnel vision. Most companies can track what their direct carriers and suppliers are doing. But disruptions rarely start at Tier 1. They cascade from sub-tier suppliers, raw material shortages, or regional events that are invisible without multi-tier mapping.

-

Poor data quality feeding AI tools. Companies rushing to deploy AI and digital twins for predictive logistics are discovering that these tools are only as good as the data flowing into them. Garbage in, garbage out — and when your data is fragmented across disconnected systems, even the most sophisticated AI produces unreliable forecasts.

What Top Performers Do Differently

The 6% of organizations with full visibility aren't using magic technology. They're doing three things that the other 94% aren't.

1. Single Platform, Multiple Modes

Top performers consolidate their logistics operations onto a unified platform that handles ocean, air, truck, and warehouse data in one place. Instead of logging into five carrier portals and reconciling spreadsheets, they get a single dashboard that updates in real time across every shipment, every mode, every partner.

This isn't just convenient — it's foundational. Without a unified data layer, every downstream capability (analytics, alerts, exception management) is built on shaky ground.

2. Multi-Tier Supplier Mapping

Leading companies don't stop at knowing who their direct suppliers are. They map their supply network two, three, even four tiers deep. When a factory fire in a sub-tier supplier's facility threatens a critical component, these companies know about it before the disruption reaches their dock.

The World Economic Forum notes that major supply chain disruptions lasting longer than a month now occur every 3.7 years on average. Companies with multi-tier visibility can start mitigating these disruptions days or weeks before their less-visible competitors even realize there's a problem.

3. Clean Data as a Strategic Asset

Top performers treat data quality not as an IT problem but as a strategic priority. They invest in standardized data formats, automated validation, and real-time error correction before feeding information into analytics and AI tools.

This approach pays compound dividends. Clean, connected data enables accurate demand forecasting, reliable ETA predictions, proactive exception management, and meaningful carbon tracking — capabilities that remain out of reach for companies drowning in dirty, disconnected data.

The Cost of Staying Blind

The financial case for visibility is no longer theoretical. Nearly 80% of organizations experienced at least one supply chain disruption in the past year, according to the Business Continuity Institute. Each blind spot in the supply chain represents a potential revenue leak — whether from delayed shipments, missed contract compliance, excess safety stock, or reactive (rather than proactive) disruption management.

In an environment where tariffs can shift overnight, geopolitical events can close shipping lanes, and consumer expectations demand real-time tracking, the companies without end-to-end visibility aren't just operating at a disadvantage. They're operating on borrowed time.

Closing the Gap with Integrated Visibility

The path from fragmented to fully visible doesn't require replacing every system overnight. It starts with consolidating logistics data onto a platform that can ingest, normalize, and connect information across carriers, modes, and partners.

CXTMS was built for exactly this challenge. By bringing rate management, shipment tracking, documentation, and partner collaboration into a single integrated platform, CXTMS gives logistics teams the end-to-end visibility that 94% of organizations are still struggling to achieve — without the multi-year integration projects that typically stand in the way.

Ready to close the visibility gap? Contact CXTMS for a demo and see your entire supply chain in one place.