Composable Supply Chain Architecture: Why Modular, API-First Logistics Platforms Are Winning in 2026

The monolith is cracking. For decades, supply chain organizations locked themselves into massive, all-in-one software suites — spending years on implementations that were outdated before they went live. In 2026, that model is breaking apart, and a new architectural philosophy is taking its place: composable supply chain architecture.

The $36 Billion Question: Why Monolithic Suites Are Losing Ground

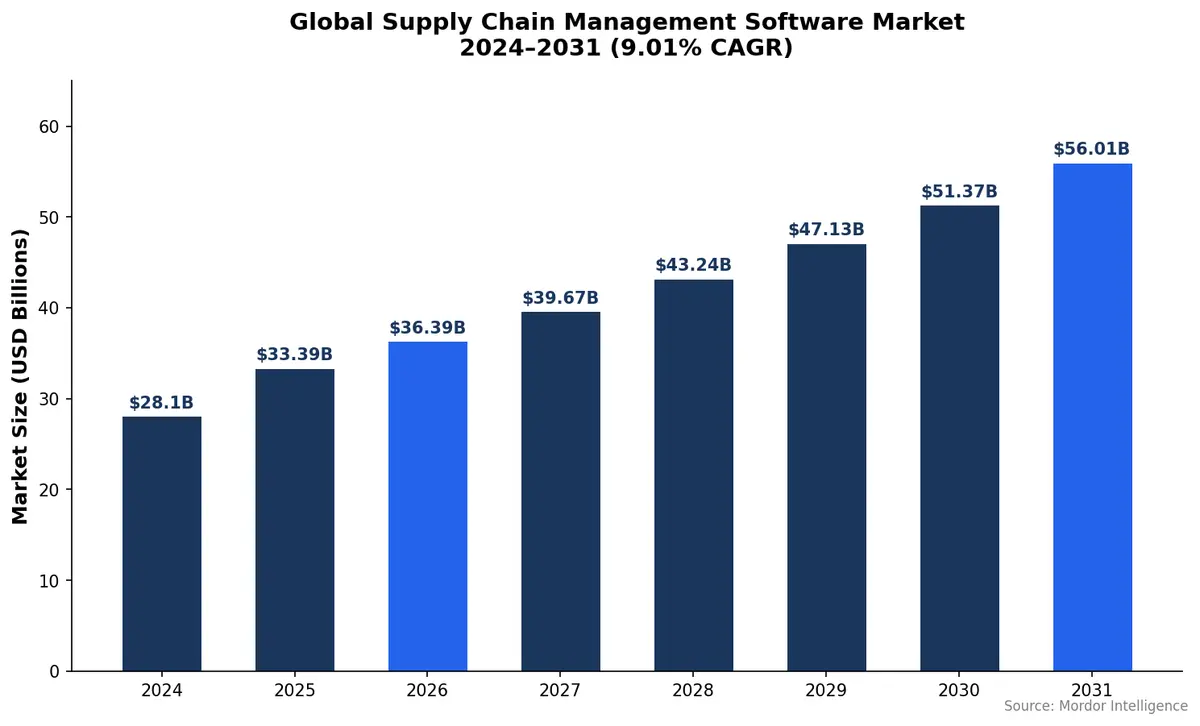

The global supply chain management software market is estimated at $36.39 billion in 2026, growing to $56.01 billion by 2031 at a 9.01% CAGR, according to Mordor Intelligence. But where that money flows is changing dramatically.

Traditional monolithic platforms — where TMS, WMS, OMS, procurement, and analytics are welded into a single vendor's ecosystem — are losing market share to modular alternatives. The reason is simple: business needs change faster than monoliths can adapt.

A Gartner survey found that only 29% of supply chain organizations have built the capabilities needed for future performance. The remaining 71% are trapped in rigid systems that can't keep pace with disruption. Composable architecture offers the escape route.

What Composable Supply Chain Architecture Actually Means

Composable architecture borrows from a concept Gartner calls Packaged Business Capabilities (PBCs) — self-contained software components that represent a well-defined business function recognizable to business users, not just IT teams.

Instead of buying one vendor's entire suite, organizations assemble their logistics stack from best-of-breed modules:

- A TMS module from one provider for route optimization and carrier management

- A WMS component from another for warehouse orchestration

- A visibility layer that aggregates data from IoT sensors, carrier APIs, and ERP systems

- An AI analytics engine that plugs into any data source via standardized APIs

Each module is independent, API-connected, and replaceable without rebuilding the entire system. Think of it as LEGO blocks for logistics — snap in what you need, swap out what you don't.

The MACH Principles Driving Logistics Forward

The composable movement in supply chain follows the MACH architecture principles that transformed e-commerce: Microservices, API-first, Cloud-native, and Headless.

Microservices Over Monoliths

Rather than a single application handling everything from freight rating to invoice processing, microservices break each function into small, independently deployable services. When your freight audit process needs an upgrade, you update that service alone — no downtime across your entire platform.

API-First by Design

API-first means every capability is accessible through well-documented, standardized interfaces. Carriers, warehouses, customs brokers, and trading partners connect through APIs rather than EDI flat files or custom point-to-point integrations. SAP's 2026 blueprint for supply chain resilience emphasizes AI-ready data models and network-wide data quality — both of which depend on API-first architectures to function at scale.

Cloud-Native Scalability

Cloud-native logistics platforms scale elastically with demand. Peak shipping season? The platform scales up. Quiet months? It scales down. No more paying for capacity you don't use or scrambling when volumes spike.

Real-World Benefits: What the Numbers Show

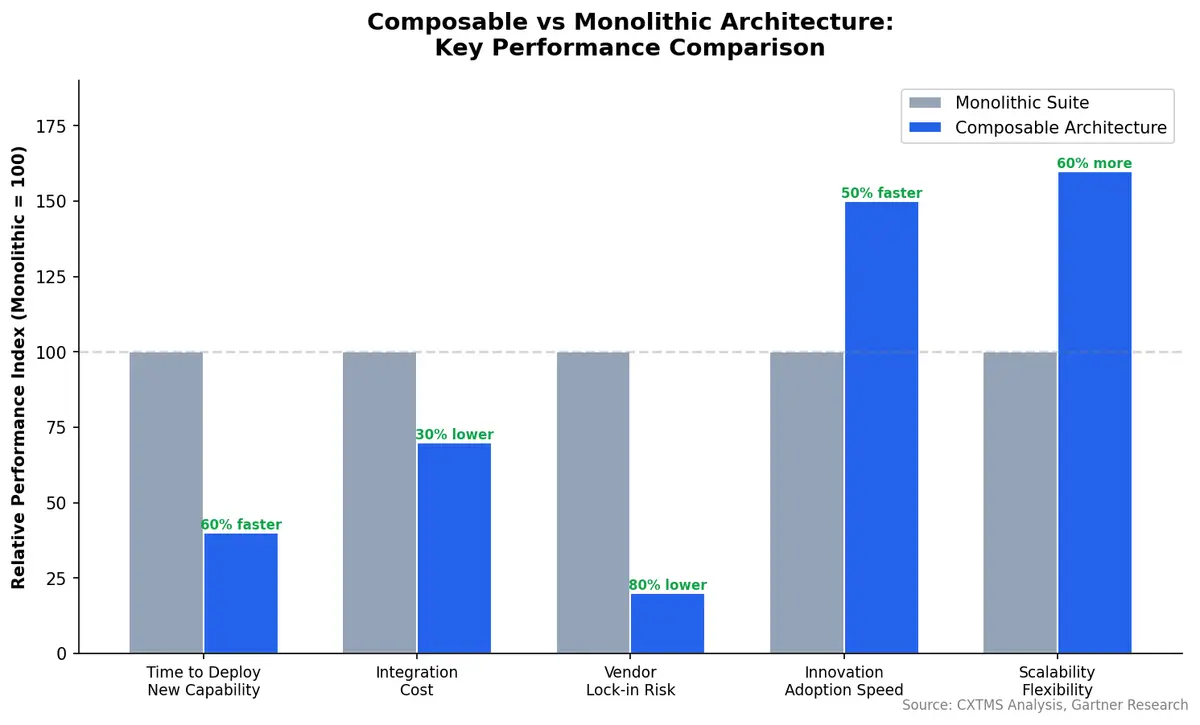

Organizations adopting composable supply chain architectures are seeing measurable results:

- 60% faster time-to-deploy for new logistics capabilities compared to monolithic upgrades, which typically require 12-18 month implementation cycles

- 30% reduction in integration costs by replacing custom point-to-point connections with standardized API meshes

- Vendor lock-in elimination — the ability to swap any component without rebuilding adjacent systems

The rising cloud-first adoption among SMEs is accelerating this shift. According to Mordor Intelligence, cloud platforms remove up-front capital barriers and provide elastic computing power, allowing smaller shippers to access analytics and AI that were once exclusive to enterprise players. This SME onboarding creates a multiplier effect across the entire supply chain ecosystem.

Why "Best-of-Suite" Lost to "Best-of-Breed"

The old argument for monolithic suites was integration simplicity — one vendor, one data model, one support contract. But that argument collapsed under three realities:

-

No single vendor excels at everything. The best TMS provider rarely builds the best WMS. Composable architecture lets you pick the leader in each category.

-

Innovation cycles differ. AI-powered freight optimization evolves monthly. ERP modules evolve annually. Coupling them together means the fast mover is held back by the slow one.

-

Disruption demands agility. When a new trade regulation drops or a port closes overnight, organizations need to plug in new compliance modules or reroute through alternative networks within days, not quarters.

Gartner's research on composable modularity confirms this trend: organizations that adopt composable principles outperform peers in revenue growth by 7.7% because they can seize opportunities faster.

Building Your Composable Logistics Stack

Transitioning from monolithic to composable doesn't happen overnight. Here's a practical roadmap:

Phase 1: API-Enable Your Core. Wrap existing systems with API layers. Your legacy ERP doesn't need to be replaced — it needs to be accessible through modern interfaces.

Phase 2: Identify Bottleneck Modules. Which capability causes the most pain? Start there. If freight audit takes weeks instead of hours, deploy a specialized freight payment module alongside your existing system.

Phase 3: Establish a Data Fabric. Gartner recommends data fabric architecture as the foundation for composable supply chains — flexible, modular by design, and able to evolve with business needs.

Phase 4: Orchestrate with AI. Once modules are API-connected, AI orchestration layers can coordinate workflows across them — routing decisions, exception handling, and predictive adjustments all happen automatically.

CXTMS: Built Composable From Day One

CXTMS was designed on composable principles before composable was a buzzword. Every module — from carrier management and freight audit to real-time visibility and document processing — operates as an independent, API-first component.

Need to connect a new carrier network? Plug it in. Want to add AI-powered rate optimization to your existing workflow? It slots in without touching your WMS integration. Running multiple clients with different requirements? Each gets a tailored composition of modules from the same platform.

This isn't just architectural philosophy — it's how modern logistics operations stay ahead of a $36 billion market that's evolving faster than any monolithic suite can follow.

Ready to build a composable logistics stack that adapts as fast as your business? Contact CXTMS for a demo and see modular, API-first logistics in action.