Supply Chain Decision Intelligence: Why Real-Time Decisioning Is Replacing Dashboards and BI Tools

Static dashboards are dying. The supply chain leaders who spent millions building beautiful BI visualizations are discovering an uncomfortable truth: knowing what happened yesterday doesn't help you decide what to do right now. In 2026, a new category of technology — decision intelligence — is replacing passive reporting with systems that autonomously make, validate, and execute supply chain decisions in real time.

From Dashboards to Decisions: The Four-Stage Evolution

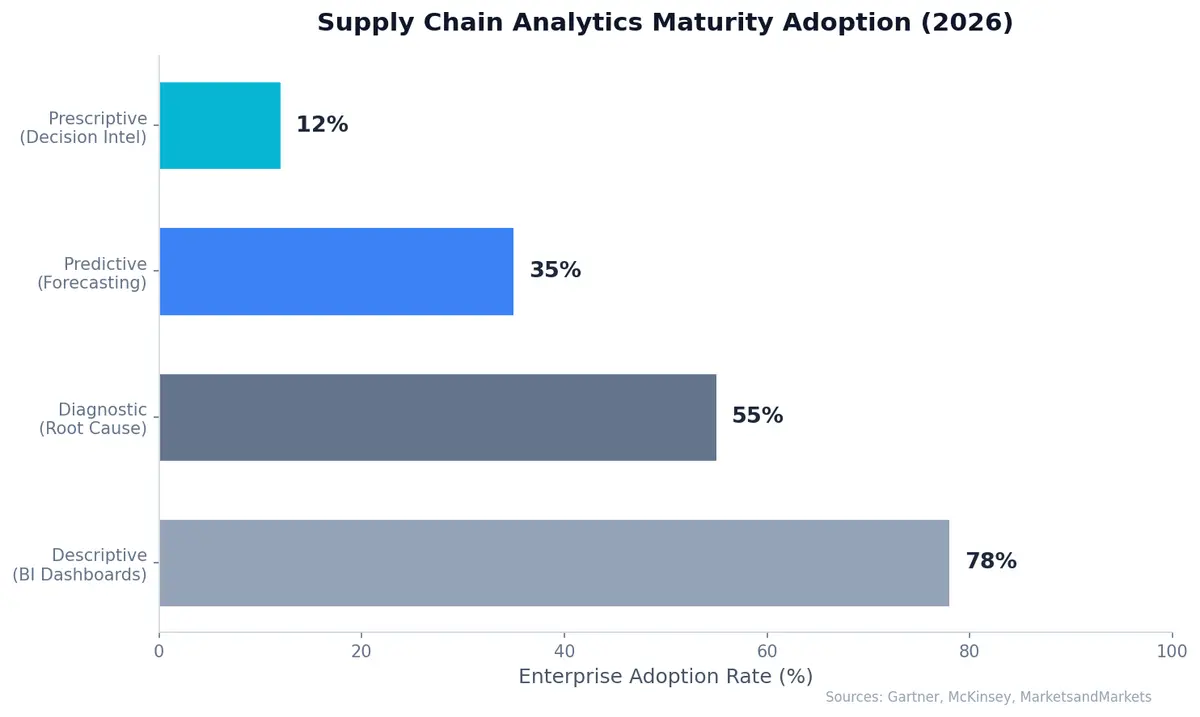

Supply chain analytics has evolved through four distinct stages, and most organizations are stuck at stage two:

- Descriptive analytics — What happened? (Traditional BI dashboards)

- Diagnostic analytics — Why did it happen? (Root cause analysis)

- Predictive analytics — What will happen? (Forecasting models)

- Prescriptive/Decision intelligence — What should we do, and do it automatically?

The jump from stage three to stage four is where the real transformation happens. Predictive analytics tells you a port delay is likely; decision intelligence automatically reroutes shipments, adjusts inventory buffers, and notifies affected customers — all before a human opens their laptop.

According to MarketsandMarkets, the global decision intelligence market was valued at $13.3 billion in 2024 and is projected to reach $50.1 billion by 2030, growing at a CAGR of 24.7%. The supply chain vertical is one of the fastest-growing segments, driven by the need for autonomous, real-time decision-making across increasingly complex global networks.

Why Dashboards Aren't Enough Anymore

The core problem with traditional BI tools isn't the data — it's the decision latency. Consider what happens when a shipment is delayed:

- Dashboard approach: An analyst notices the delay on a morning report, investigates root causes, emails the operations team, who then manually adjusts routes and contacts carriers. Total time: 4–8 hours.

- Decision intelligence approach: The system detects the delay in real time, simulates alternative routes, selects the optimal option based on cost, SLA, and capacity constraints, and executes the change autonomously. Total time: seconds.

Gartner's Market Guide for Analytics and Decision Intelligence Platforms in Supply Chain reinforces this shift, noting that functional teams are increasingly seeking near-real-time, cross-functional decision-making capabilities. Meanwhile, McKinsey's research indicates that AI-based forecasting and decision systems reduce supply chain errors by 20–50% compared to traditional methods, while high-quality data-driven models save 3–8% in overall logistics costs. When you multiply those percentages across a $10 billion supply chain, the numbers become impossible to ignore.

The shift is also being driven by volatility. As the Supply Chain Management Review noted in January 2026, the key trend of 2025–2026 is "predictive orchestration" — moving beyond siloed procurement, manufacturing, and logistics systems toward unified AI that predicts disruptions and orchestrates responses across the entire value chain.

Aera's Decision Cloud: Autonomous Decisions at Hershey

One of the most compelling real-world examples comes from The Hershey Company. In February 2026, Food Navigator USA reported that Hershey deployed Aera Technology's Decision Cloud to automate supply chain decisions across demand planning, inventory management, and fulfillment.

What makes Aera's approach notable is its use of autonomous agent teams that self-assemble based on the decision at hand. Rather than pre-programming every workflow, the platform deploys learning agents that optimize policies and governance agents that enforce compliance — all without human intervention for routine decisions.

The Hershey deployment demonstrates three critical capabilities of decision intelligence:

- Autonomous decision execution — Routine decisions (reorder points, carrier selection, demand adjustments) happen automatically

- Simulation-validated choices — Before executing, the system simulates outcomes using multidimensional models integrated with agentic AI

- Human escalation for exceptions — Only novel or high-risk decisions are surfaced to human operators, with full context and recommended actions

Gartner has recognized the maturation of this category by publishing both a Market Guide for Analytics and Decision Intelligence Platforms in Supply Chain and, more recently, a Magic Quadrant for Decision Intelligence Platforms — signaling that the market has moved beyond the early-adopter phase.

Prescriptive vs. Predictive: Why Recommendations Aren't Enough

Many supply chain teams believe they've achieved decision intelligence because their tools generate recommendations. But there's a critical difference between a system that says "you should reroute through Atlanta" and one that actually executes the reroute, updates the carrier, adjusts the ETA, and triggers downstream inventory rebalancing.

True decision intelligence platforms close the loop between insight and action. They combine:

- Decision modeling — Explicit frameworks for how decisions should be made, including constraints, objectives, and trade-offs

- Real-time data integration — Live feeds from TMS, WMS, ERP, IoT sensors, and external sources (weather, port congestion, market prices)

- Simulation engines — Digital twin capabilities that test decisions against multiple scenarios before execution

- Autonomous execution — API-driven actions that implement decisions across connected systems without manual intervention

The prescriptive analytics market alone was valued at $1.97 billion in 2018 and is projected to reach $12.35 billion by 2026, according to Allied Market Research — a 26.6% CAGR that reflects the urgency enterprises feel to move beyond passive insights.

Building Your Decision Intelligence Roadmap

Transitioning from dashboards to decision intelligence doesn't happen overnight. Here's a practical framework for supply chain leaders:

Phase 1: Decision inventory. Catalog every recurring decision in your supply chain — carrier selection, reorder triggers, route optimization, demand adjustments. Identify which are routine (high-volume, rule-based) versus strategic (complex, context-dependent).

Phase 2: Automate the routine. Start with high-frequency, low-risk decisions. Automated carrier selection based on real-time rate and capacity data is a common entry point, typically delivering 5–15% cost savings within the first quarter.

Phase 3: Augment the strategic. For complex decisions — network redesign, supplier diversification, capacity planning — deploy AI-augmented tools that simulate scenarios and present options with confidence scores, keeping humans in the loop.

Phase 4: Continuous learning. Implement feedback loops where decision outcomes are measured against predictions, and the models improve automatically. This is where the compounding value of decision intelligence emerges.

How CXTMS Powers Real-Time Supply Chain Decisioning

CXTMS is built for the decision intelligence era. Rather than presenting logistics data on static dashboards, CXTMS provides an intelligent decision layer that sits across your entire transportation network:

- Automated routing decisions that factor in real-time carrier capacity, cost, transit time, and service-level requirements

- Exception-driven workflows that only surface decisions requiring human judgment, while handling routine operations autonomously

- Prescriptive analytics that don't just flag problems but recommend and execute optimal responses

- API-first architecture that integrates with your WMS, ERP, and carrier systems to close the loop between decision and action

The future of supply chain management isn't better dashboards — it's fewer dashboards. When decisions are made in real time by intelligent systems, the role of the supply chain professional evolves from monitoring screens to governing strategy.

Ready to move beyond dashboards and into autonomous supply chain decisioning? Contact CXTMS for a demo of our decision intelligence capabilities.